3D Printed Organs On Demand — One Step Closer To Reality

By Chuck Seegert, Ph.D.

Over 120,000 people are currently on waiting lists for organ transplants. Unfortunately, between January and April of this year, only about 10,000 were able to get the transplants they needed.

The science of biofabrication, or the fabrication of artificial organs, is an emerging field that can address this pressing need, and an international research team now appears to have brought the manufacturing of artificial organs one step closer to reality.

Biofabrication is a term used to describe a 3D bioprinting process that precisely places layers of cells containing spheroids into a matrix. Bioprinting is used to form structures that consist of a matrix and cells interspersed within the matrix as desired or designed.

There are a few methods of performing the biofabrication process, but inkjet printing using a special solution called bioink is currently the most promising tool in use. Bioink is a mixture of an ink medium along with living cells that are deposited during printing.

Inkjet printing has been used to print many different types of living cells, including hamster ovary cells and human fibroblasts. This technology, however, has lacked an intimate understanding of the physics that govern the deposition of bioink. It is important to understand this behavior so that a full evaluation of bioink printing and biofabrication as a core technology can take place.

In a new study published in the American Chemical Society’s journal, Langmuir, the efforts of an international research team led by professor Yong Huang are described in detail. During the inkjet printing process, droplet formation of the cell-filled bioink is critical. Understanding the behavior of this system was the main goal, and the team focused on four key variables, including breakup time, droplet size, droplet velocity, and satellite formation. Time-resolved imaging was the method used to collect this data.

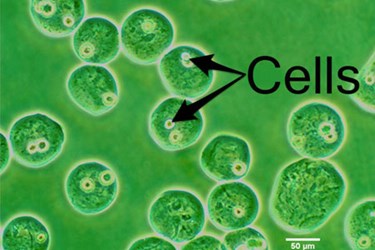

The researchers believed that cell concentration may be involved in the physics of droplet formation. Therefore, the bioink was tested at four different cell concentrations, including zero cells, 1 by 106, 5 by 106, and 1 by 107 cells/mL.

To gain another level of understanding on how cells, as a physical component of bioink, have an influence on droplet formation, they were compared to solutions containing polystyrene microbeads. Cells are flexible and relatively compliant compared to microbeads, which are rigid. The printing of the microbeads was performed under the same conditions and at the same concentrations as the cell solutions, allowing the team to focus on the rigidity of the cells and their contribution to the droplet formation.

Overall, increasing the cell concentration in the bioink led to smaller droplet sizes and a lower droplet velocity, while the breakup time increased and the satellite droplet formation was suppressed. Comparing cells to polystyrene beads revealed that cell-laden bioink has less ejected fluid volume, lower droplet velocity, and greater breakup time.

Artificial organ development is receiving a lot of focus within the biomedical and bioengineering community due to the urgent needs of transplant patients. Research has focused on depositing cells in 3D matrices, as well as 3D printing support structures like the 3D vasculature needed to maintain them within their matrix.