3D Printing Transforms Cellphone Into A Microscope

By Chuck Seegert, Ph.D.

A 3D printable clip has been developed to turn cellphone cameras into powerful microscopes, and its low-cost components are ideal for applications where contamination can occur.

While there are a few options that can be used with cellphones to turn them into microscopes, they are generally bulky and suffer from a number of drawbacks. These low-power solutions are notoriously difficult to align, which was the driving force behind a recent project at Pacific Northwest National Laboratories (PNNL), according to a recent press release.

"We believe it can fill a need for professional first responders, and also for teachers and students in the classroom, health workers and anyone who just wants an inexpensive microscope readily available," said Rebecca Erikson, an applied physicist at PNNL, in the press release.

The project was funded by an internal research and development budget that addresses the needs of the Department of Homeland Security. Low cost was a key driver, since it needed to be disposable in order to study toxic or infectious samples.

"We interviewed a lot of first responders, public health labs and civil support teams," said biochemist Cheryl Baird in the press release. "They told us the first thing they do when a suspicious powder sample gets to the lab, is to put it under the microscope. An inexpensive, yet powerful microscope in the field could be used to quickly determine whether the material is a threat or a hoax. Combine the microscope with the picture sharing capability of a smart phone and now practically anyone can evaluate a sample at the source and have a trained microbiologist located in a lab elsewhere interpret the results within minutes."

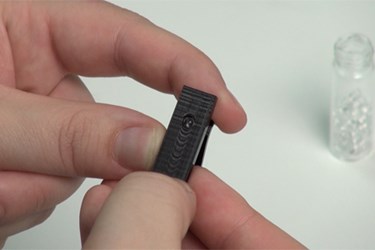

The 3D printable, plastic microscope clip is designed to slip over the camera of a cellphone, adding thickness to the phone that is about equal to a phone case, according to the press release. The clip is inserted with a spherical glass ball that is commercially available. Materials for each microscope cost less than $1.00 and can be capable of 1000x magnification. Other designs will provide 350x and 100x magnification for different applications.

The PNNL design is open access, and all specifications and part numbers needed to make a microscope are available as well. Some commercial applications may need to be licensed.

Low-cost diagnostics have continued to gain prominence in the medical device research space. Recently, a paper-based cancer test was developed to provide diagnosis in the developing world. Cellphones and apps are also becoming part of this effort, given their ubiquitous presence and capabilities. In another article published on Med Device Online, cellphones were combined with a low-cost device to provide an array of laboratory tests that could be communicated by many different electronic methods.

Image Credit: PNNL