Insect-Inspired Nanoscale Spikes Kill Bacteria On Med Device Surfaces

Taking inspiration from cicada wings, scientists have developed a method for molding FDA-approved polymers for medical device and implant surfaces that kill bacteria without chemical treatment. According to scientists at the University of California, Irvine (UCI), the process is scalable for industry and is commercially feasible.

Antibiotic-resistant infections sicken at least 2 million patients per year and result in more than 23,000 deaths, according to a study by the Centers for Disease Control and Prevention (CDC). Because contact with medical instrumentation and devices increases a patient’s risk of developing a healthcare-related infection (HAI), researchers have been focusing on ways of making device surfaces cleaner and safer.

Some research suggests that bioplastic from proteins like egg whites, soy, or wheat has more anti-bacterial properties than petroleum-based plastics. A team from Harvard developed a self-replenishing oily coating to discourage bacterial build-up, and a team of French scientists introduced a multi-layer coating that protects against bacteria, fungus, and yeast.

In a 2013 study in Biophysical Journal, a team of Spanish and Australian scientists reported the discovery of a matrix of nanoscale spikes on the surface of cicada wings. Bacteria that landed on the blunted spikes sagged over the edges and eventually ruptured, said the researchers, killing microbes by no other mechanism than the shape of the biomaterial.

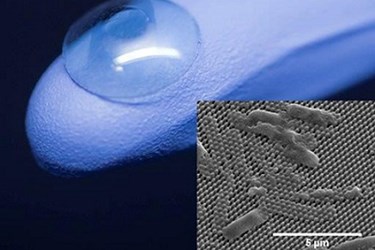

According to a presentation for the American Chemical Society (ACS), UCI Professor Albert Yee and his team came across the cicada research when investigating materials for a corneal implant. Using a flexible mold to replicate the cicada’s spikes, researchers made an artificial cornea with a curved polymethyl methacrylate (PMMA) surface that could kill bacteria in the eye without harming other cells.

“Using this technique, you can create tiny surface texture with a very precise geometry over a very large area,” graduate student Mary Dickson commented in the presentation. “We found that ordinary PMMA could kill E coli bacteria without any special chemical modifications.”

Though other research groups have experimented with similar antibacterial nanopillar surfaces, Yee maintained that their processes are not useful with ordinary polymer surfaces and cannot be easily scaled up to meet industrial demands.

The mold developed at UCI “is robust, inexpensive and can be used in industrial production. So it can now be applied to medical devices that could improve people’s quality of life,” said Dickson, in a press release.

In a recent progress report , the CDC reported that initiatives launched in 2009 to reduce the spread of HAIs had been successful but that “more action is needed at every level of public health to reach the new Health and Human Services (HHS) proposed targets for December 2020.”

In an article published last year on MDO, Lise Moloney, director of business development at Sciessent, said that there is no “one-size-fits-all” approach to antibacterial device surfaces and what works for one manufacturer may not work for another.

“With the demand for antimicrobial-protected medical devices growing, manufacturers are exploring how they can develop new technologies to meet the needs for their customers,” said Moloney.

Image credit: Jonathan Pegan (cornea) and Mary Nora Dickson (inset)