Researchers Create Coating Material To Prevent Blood Clots Associated With Implanted Devices

By Matthew Chin

A team of researchers from UCLA and the University of Michigan has developed a material that could help prevent blood clots associated with catheters, heart valves, vascular grafts and other implanted biomedical devices.

Blood clots at or near implanted devices are thought to occur when the flow of nitric oxide, a naturally occurring clot-preventing agent generated in the blood vessels, is cut off. When this occurs, the devices can fail.

Some researchers have sought to solve this problem with implantable devices that gradually release nitric oxide, but their supply of the agent is necessarily limited. Instead, the UCLA–Michigan team focused on an ultra-thin coating for the devices that acts as a chemical catalyst, generating clot-preventing molecules that can mimic the function of blood vessels.

The researchers suggest this could offer a long-lasting and cost-effective solution to the problem of these blood clots. The study was published online this month in the journal Nature Communications.

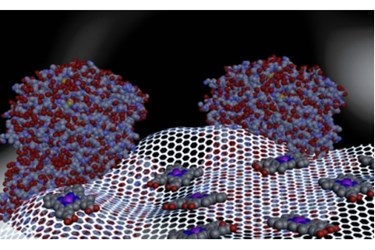

For the device coating, the team used sheets of graphene, a one-atom-thick layer of graphitic carbon, into which they integrated two components — haemin and glucose oxidase. Both work synergistically to catalyze the production of nitroxyl, which can be used inside the blood like nitric oxide, although it contains one less electron. Nitroxyl has been reported as being analogous to nitric oxide in its clot-preventing capability.

"This may have interesting applications in a wide range of biomedical device coatings," said Teng Xue, the study's lead author and a UCLA graduate student.

"This work demonstrates how the exploration of nanomaterials, combined with knowledge in chemical catalysis and biochemistry can lead to unique functional structures benefiting biomedical research and beyond," said principal author Yu Huang, an associate professor of materials science and engineering at the UCLA Henry Samueli School of Engineering and Applied Science. "We will continue to explore molecular assemblies and conjugated catalytic systems as analogs to the functional proteins that can facilitate chemical transformations under mild conditions, like nature does."

Additional authors of the research included Mark E. Meyerhoff, professor of chemistry at the University of Michigan; UCLA graduate students Bo Peng, Si Yang, Min Xue, Xing Zhong, Shan Jiang, Sergey Dubin, Chin-Yi Chiu and Lingyan Ruan; UCLA postdoctoral scholar Yongquan Qu; and professors Jeffrey Zink, Richard Kaner and Xiangfeng Duan of the UCLA Department of Chemistry and Biochemistry. Huang, Duan, Kaner and Zink are all members of the California NanoSystems Institute at UCLA. Duan holds UCLA's Howard Reiss Career Development Chair in Chemistry and Biochemistry.

The research was supported by grants from the National Institutes of Health.

About The UCLA Henry Samueli School of Engineering and Applied Science

The UCLA Henry Samueli School of Engineering and Applied Science, established in 1945, offers 28 academic and professional degree programs and has an enrollment of more than 5,000 students. The school's distinguished faculty are leading research to address many of the critical challenges of the 21st century, including renewable energy, clean water, health care, wireless sensing and networking, and cyber-security. Ranked among the top 10 engineering schools at public universities nationwide, the school is home to eight multimillion-dollar interdisciplinary research centers in wireless sensor systems, wireless health, nanoelectronics, nanomedicine, renewable energy, customized computing, the smart grid, and the Internet, all funded by federal and private agencies and individual donors.

Original Release: http://newsroom.ucla.edu/portal/ucla/new-coating-material-developed-254869.aspx.

Source: UCLA