What Should Your Wearable Wear? Choosing Materials For Medical Device Enclosure

By Nabil Khan, Software Engineer, Anuva Innovations

Material selection may be one of the most difficult decisions to make about your wearable device design. There are a large amount of basic plastics and metals to choose from. But when you consider additives, alloys, and blends, the list becomes downright intimidating. If you are searching for some guidance or are preemptively curious how to make such a decision, here are the three areas to help break it down:

The User

First and fore most you need to detail your user – who will be wearing your device? If you have a gender- or age-specific user, this will affect the size, shape, and weight of the device material. You should also consider exactly what the device will come in contact with on the user. Will it be worn on someone’s belt loop, or does it apply straight to the skin and need to be biocompatible? Lastly, how long or for how many uses should you expect your device to function? Whether you decide you need a disposable device or an indestructible one, you can eliminate an entire class of materials with this question.

Next you will need to consider the exposure the device will get in the users’ environment – where will they be wearing it? Think about how it will need to withstand temperature changes, humidity, radiation, and potential hazards (fire, water, etc.). Along with effects of exposure, consider the effect your device will have on the surrounding environment: will it need to be sterilized or cleaned, and how often? These problems can be often addressed with material additives, but should still be well-defined early in the decision-making process.

If you decide that your device is intended to be worn by young children then you can imagine a material that is lightweight and brightly colored. This definition, however, also tells you that the device material should be durable or easily and inexpensively replaced to accommodate the typical carelessness of a young child. Even though the user definition here is general, it has enormously reduced your possible choices.

The Production

Now that you have found some clarity by defining your user, take a step backward and think about how this device might be manufactured to fit your needs. This is where you should heavily consider the cost of the material through two specifications. First, you will need to provide an intended scale of production (do you anticipate needing 100 units or 100,000?). Second, you will need to define if your device or any components of your device are intended to be reusable. The material you choose will limit the possible production methods you can use, so these two factors will help you find the most appropriate manufacturing process for your needs and, thus, an applicable material that falls in line with this process.

The type of material and the type of manufacturing process you can use are interdependent, but both rely directly on your scale of production. You should use this production scale to narrow down the possibilities and then weigh the costs and benefits of each option until you find what is best for your device.

The Worst-Case Scenario

Now that you’ve answered all the basic questions, you can probably pick out a handful of appropriate materials that could work. But that’s not enough – you need a perfect fit! You want to guarantee the safety of your users while they wear your device, which means it has to be tested for changes in what you might call the “worst-case scenario.” Here is where it will be most helpful to have a regulation-loving team of engineers on your side. The testing requirements will vary depending on your application, so it is important to map out early in the development which tests your device will need to pass. When these are decided on, you have everything you need to pick the perfect material.

Often, there will still be more than one material that is suitable for your application, even after map-ping out all of the areas listed above. If this is the case, one further step you can take to choosing the best material out of the bunch is by using a tool called a Pugh Chart. Here is how it works:

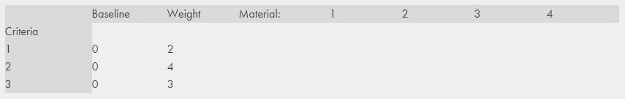

1. Start with your material choices listed across the top and your criteria for comparison (the answers you came up with above) listed down the side. In front of the material choices, make a column for baseline values and weighted values for each criteria. (See figure below.)

2. Next to each of your criteria listed, add a baseline value to define your scale (should be the same for all criteria) and then score each according to its importance to you and the device function in the weight column. (See figure below.)

3. For each material that meets your criteria, mark with a +1. For each material that takes away from your criteria, mark with a -1. For each material that neither accomplished nor diminishes your criteria, mark with a zero.

4. Multiply the weight value across the materials.

5. Add each material column and whichever has the highest sum is your winner!