Graphene Biosensors — The Next Frontier In Medical Diagnostics?

By Jim Pomager, Executive Editor

Believe it or not, graphene — the übermaterial expected to revolutionize healthcare and just about every other industry imaginable — will officially celebrate its 10th birthday next month.

In October 2004, Andrei Geim, Kostya Novoselov, and collaborators published their seminal graphene paper in Science magazine, announcing the first successful isolation of an effectively two-dimensional, one-atom-thick sheet of pure carbon in the lab. (Geim and Novoselov famously used Scotch tape to peel away layers of graphene from a carbon block.) Their breakthrough and subsequent work with graphene earned Geim and Novoselov the Nobel Prize in Physics six years later.

Although there has been a ton of hyperbole surrounding graphene and its potential, the material’s properties are truly remarkable. It is 1 million times thinner than paper and 100 times stronger than steel. It is highly flexible, impermeable to gasses and liquids, and an extraordinarily good conductor of both electricity and heat. It may be the most unique and versatile substance the world has ever known.

For this reason, graphene has become one of the hottest areas of materials science research and development over the past decade. Scientists around the world have been exploring the use of graphene as a building block for faster computer chips, longer-lasting batteries, flexible touchscreen displays, rust- and radiation-proof coatings, water filtration membranes, lightweight building materials and aviation components, miniaturized sensors … and the list goes on.

Much of the graphene R&D has revolved around two objectives. The first is finding a way to manufacture the substance quickly, efficiently, inexpensively, and at scale. (A whole lot of Scotch tape and carbon block doesn’t appear to be the answer.) The second and more obvious is identifying the best applications for graphene — where it can address unmet market needs or provide superior performance over existing technologies.

Recently, I was introduced to a company that claims to be close to achieving both goals, and its work could have considerable influence on how graphene is used in healthcare, particularly in the area of in vitro diagnostics.

Developing A Better Graphene Manufacturing Process

Graphene Frontiers is an advanced materials and nanotechnology company that was spun out of the University of Pennsylvania (Penn) in 2011 by cofounders A.T. Charlie Johnson and Zhengtang Luo, along with CEO Michael Patterson. Johnson, the director of Penn’s Nano/Bio Interface Center and a professor in the Department of Physics and Astronomy, is one of the world’s foremost experts on graphene and carbon nanotube electronics. Luo, now a professor at the Hong Kong University of Science and Technology, was then a postdoctoral researcher in Johnson’s lab and the inventor of Graphene Frontiers’ core technology. Patterson was a senior VP at Bank of America at the time, working on an MBA in entrepreneurial management at Penn’s Wharton School of Business.

Mike Patterson, CEO, Graphene Frontiers

One of the company’s two primary aims is to speed and scale the graphene film production process. Based on Johnson and Luo’s university research, Graphene Frontiers has developed a proprietary chemical vapor deposition (CVD) and transfer process for growing high-quality, large-area graphene films. The technique is distinctive in that it works at atmospheric pressure — unlike the vacuum deposition approach used by other graphene manufacturers, which requires expensive capital equipment to maintain low pressure. In addition, Graphene Frontiers’ patented etch-free transfer method eliminates the need to consume the copper substrate used for production. Thanks to these manufacturing advantages, the company is able to produce graphene more efficiently, with improved material quality and at lower cost.

Speaking of cost, Graphene Frontiers’ process can already manufacture graphene at commercial/industrial scale, though it currently runs in the dollars or tens-of-dollars per square inch to produce. The company is striving to get the figure down to pennies per square inch. Its effort is being aided by the National Science Foundation (NSF), which awarded Graphene Frontiers a nearly $750,000 grant last September to adapt its CVD approach into a roll-to-roll process, thus enabling large-scale production.

“We have just completed the first year of our NSF-funded roll-to-roll production project and expect to announce our commercialization partners by the end of the year,” Patterson told me. “We have adapted our processes for wafer-scale device fabrication. Our unique capabilities position Graphene Frontiers as a leader in graphene device production.”

Sensors: Graphene’s Ideal Application

The other area of focus for Graphene Frontiers is the development of graphene-based sensors, both chemical and biological. I recently spoke with Victoria Tsai, Ph.D., VP of business strategy and scientific research, who is leading the company’s biosensor technology development. “Because graphene is so conductive — it's the best conductor of heat and electricity of all the materials out there — it's a great material for using in sensor applications,” she explained.

Dubbed “Six,” the company’s sensor technology consists of a field effect transistor (FET) with a graphene channel. In Graphene Frontiers’ biosensors, antibodies and other types of proteins are attached to the surface of the graphene channel through a proprietary process that basically creates defects in the material, which then enables covalent bonding between proteins and the graphene.

Here’s how the biosensor works: Depending on the application, a blood, cerebrospinal fluid, or urine sample is introduced to the sensor. When an antigen (e.g., a bacterial protein) in the sample binds to an antibody attached to the sensor’s graphene channel, it results in a corresponding change in the electrostatic field. An electrical current passes through the graphene, and the antigen binding to the antibody modulates that current through the graphene by its proximity and charge. By measuring that signal, the amount of antigen in the sample can be quantified, enabling disease diagnosis.

Structure of Graphene Frontiers' GFET (graphene field effect transistor)

What’s unique about these biosensors is not just their mechanism of action, but that they can achieve results very quickly and accurately, in a much smaller package than current-generation sensors. The graphene biosensors are extremely tiny, about one-tenth the size of a postage stamp. Despite their small footprint and weight, the sensors deliver lab-quality sensitivity, detecting molecules in femtomolar (fM) concentrations. (According to the company, graphene sensors enable a >100x improvement in sensitivity over existing sensors and assays.) This heightened sensitivity means that minute amounts of sample — think on the order of a drop of blood — are sufficient for accurate diagnosis.

Unlike lab tests, which typically take hours or days to provide results to healthcare providers, Six sensors deliver results in seconds, making them ideal for applications at the point of care.

“Imagine the possibilities of providing this capability to a primary care physician,” Patterson said. “Instead of sending patients to a third-party testing lab to have several vials of blood drawn and get results in several days, the physician can use a capillary [finger stick] blood sample at point of care to test for multiple biomarkers or pathogens simultaneously — and have results within minutes.”

The company believes it will be able to offer the biosensors at price points very competitive with current diagnostic technologies, and maybe even cheaper — if, as expected, they are able to further drive down the cost of graphene production and scale-up the lithography process for individual sensors. There are indirect financial benefits, as well. “Time to results and diagnoses will be much faster. This will lead to earlier treatments and improved patient outcomes, resulting in significant savings at multiple points in the healthcare system,” Tsai said.

Diagnosing Lyme Disease, Cancer, And Other Diseases

Graphene Frontiers is tailoring its technology to diagnose diseases that demand a sensitivity level unattainable using today’s biosensors. “We are going after point-of-care applications where the presence of biomarkers is too low to detect with the current technology,” Tsai told me.

One such target application is Lyme disease, a condition diagnosed in approximately 300,000 Americans each year, according to estimates from the U.S. Centers for Disease Control and Prevention (CDC). Lyme disease is currently identified through clinical symptoms and host immune response, which is conducted using the standard laboratory techniques Western blot and the ELISA laboratory techniques.

However, Western blot and ELISA detect circulating antibodies — which the patient generates in response to the bacteria — and not the bacteria itself. (Lyme disease antibodies are notoriously difficult to identify.) The Six sensors technology would pinpoint the bacteria itself, making it much more accurate than antibody-based tests. As mentioned previously, the graphene sensor would also be much faster, and it would require a smaller sample compared to standard diagnostic tests.

Victoria Tsai, Ph.D. VP of business strategy and scientific research, and Ryan Mendoza, VP of engineering, Graphene Frontiers

In addition to Lyme disease, the company is also exploring the biosensor’s ability to detect early cancer biomarkers, autoimmune diseases, and cardiovascular diseases. “Really, it's a sensor platform technology that could be customized to a disease state of interest,” Tsai explained, “and it would primarily target low-abundance, hard-to-detect biomarkers.”

Eventually, Tsai expects that numerous biosensor devices will be integrated into a multiplexed chip that could diagnose multiple conditions simultaneously. “On one small chip the size of a quarter or a dime, you would be able to assay for 25 to 100 targets simultaneously,” she said. “It would give you a comprehensive view of which proteins in a patient's system are up-regulated and down-regulated, through a single drop of blood or other body fluid.”

Finding The Right Partner

The Graphene Frontiers team continues to develop its biosensor technology in close collaboration with the university from which it was born three years ago. Penn physicians and professors are playing a major role in helping the company improve the technology and customize it for specific applications.

The bulk of their attention is currently on testing and validation — in hopes of soon landing a corporate partner to help bring the biosensors to market. “We are optimizing and testing the technology’s limits of detection and dynamic range to determine the lowest concentration we can accurately and reproducibly detect,” Tsai said. “We are gathering the data for several biomarkers to have a comprehensive characterization of our biosensor technology, and then our plan is to find a strategic partner to commercialize the technology and bring it to market.”

Graphene Frontiers is already in conversations with several diagnostics companies (though, for obvious reasons, they would not disclose the names). According to Tsai, multiple corporations are interested in potentially working with her company, but they want to see additional data before moving forward. “Our goal is to generate the necessary data in the next six months or less, and then initiate the FDA approval process,” she added. “That’s why we are looking to bring in a partner, to leverage their expertise and experience in the regulatory and commercialization processes.”

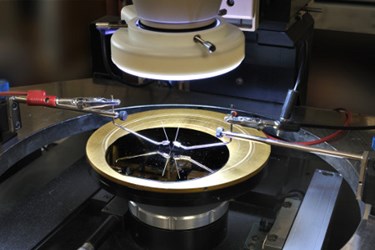

Graphene Frontiers GFETs in a probe station

At this point, Tsai is unsure about whether or not the company will be able to find a predicate for the device, allowing it to take the faster 510(k) pathway to market (as opposed to seeking premarket approval). “In one sense, it's a graphene-based sensor, so it does not have a direct predicate,” she said. “But on the other hand, if the application is to diagnose a myocardial infarction, for example, there have been other devices reviewed and approved. I've gotten mixed reviews from different sources.” She said Graphene Frontiers hopes to commercialize a product sometime in 2016 or 2017, while acknowledging that it might take longer.

A Competitive Biosensor Landscape

While Tsai said she is not aware of any other companies that are developing graphene-based biosensors (I couldn’t identify any either), there are a host of university research groups around the world creating their own unique graphene biosensors. (A great many of graphene biosensor patents have also been filed.) Plus, researchers are now exploring alternate materials as the basis for new biosensor platforms.

Earlier this year, a group from the University of California, Santa Barbara (UCSB) published research on the development of an FET-based biosensor using another two-dimensional material called molybdenum disulfide, or molybdenite (MoS2), as the sensing material. The researchers claim that their molybdenite biosensor is more sensitive, scalable, and easily mass-produced than graphene biosensors. MoS2’s edge, they say, is due to the fact that it has a band gap — it can be switched between conductive and insulated states, making it less prone to current leakage and inaccuracy. Graphene, on the other hand, has a zero band gap, meaning it cannot be turned “on” and “off.”

However, MoS2 is still poorly characterized (about five years behind graphene), and there are several factors which give graphene an advantage over MoS2, according to Tsai. "First, the carrier mobility in MoS2 is two to three orders of magnitude lower than it is for graphene, hurting sensitivity and response speed, which are very important in sensor applications," she said. "Second, it remains very difficult to produce MoS2. While micrometer- and millimeter-scale MoS2 crystals have been demonstrated, at Graphene Frontiers we are able to produce graphene as large-area sheets. Finally, MoS2 is not as stable or chemically inert as graphene — many chemicals or molecules may bond with or damage MoS2, thus hampering its sensing applications."

Chemical vapor deposition (CVD) system for growing graphene

Graphene Frontiers believes it has the early lead over MoS2 and other competitors in the race to commercialization. And once its graphene biosensors reach the market, they could fundamentally change the way diseases are diagnosed and care is delivered.

“We are very enthusiastic and optimistic about the potential of these graphene biosensors in the diagnostics field,” Tsai said. “We believe they will be transformative in the way that healthcare is delivered to patients, while cutting healthcare costs. Patients would be able to get their test results and diagnosed at the site within minutes, and if necessary, the treatment could begin immediately, thus saving valuable time.”

From there, who knows where this “wonder material” will take the medical device industry? We’re already hearing about research into graphene rubber bands for drug delivery, graphene-based implant coatings, artificial retinas made of graphene, and even graphene condoms (!). The frontier is vast, the territory largely uncharted, and the opportunity seemingly limitless.