Accelerating the Concept Phase with Solid Imaging

By Michael Eneberg, Product Manager, 3D Systems

This is the second in a four-part series of articles. The first part discussed the advantages to getting your product to market quickly, while improving product quality and reducing development costs.

Every product starts—or should start—as a concept that addresses an expressed or perceived customer need. The need can be revealed in any number of ways, from customer feedback on existing products, to focus group data, to marketing research, to raw inspiration. Customer needs can even be revealed by accident: witness the ubiquitous 3M Post-It Note, the direct descendant of failed efforts to produce a permanent adhesive.

In highly evolved manufacturing organizations, the product development process moves from this initial concept to the creation of two essential documents. One of these, the business opportunity plan (BOP), is essentially a classic business plan focused on the particular product. It documents the perceived market for the product, the competitive landscape, the marketing and sales strategies, and projected costs, revenues, and profits. In many cases, corporate executives and board members will decide whether to proceed with production based on the information (particularly the financials) in the BOP. The other, the marketing requirements document (MRD), functions as a written blueprint for the product, listing all the required features that engineers will need to include. Engineers will take their marching orders directly from the MRD.

The Need to Improve Communication

Assembling these documents—and getting them approved so that the team can proceed to the design phase—requires continual, effective communication between groups with extremely different backgrounds and objectives. Engineers need to convey their initial design ideas to product managers. OEMs need to understand how the product works with their existing products, and suggest revisions where necessary. Suppliers need to understand the product to suggest solutions and develop accurate and economical quotes and lead times. Marketing needs to "picture" the product to develop promotional and advertising concepts, design packaging, and assess the product's ability to satisfy consumer demands. Focus groups need to understand the product in order to give valuable input. Key customers and resellers need to be "sold" in order to realistically project financials.

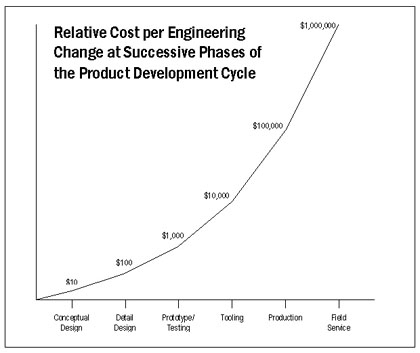

Most important, to keep total product costs at a minimum, the manufacturing staff needs to evaluate the feasibility of executing the design, to the greatest degree possible, at this initial phase. As Product Development Industry Consultant, Terry Wohlers stresses (and Figure 1 illustrates), "The cost of an engineering change increases by roughly an order of magnitude as the design progresses from one significant phase of development to the next."

Despite the power of solid modeling software, the chief obstacle to effective communication is the communications vehicle itself: the flat CAD drawing. Accurately interpreting a two-dimensional drawing as a three-dimensional object is difficult enough for experienced engineers; it's even more difficult for people without regular experience interpreting drawings, which describes just about everyone else in the loop. The greater the reliance on two-dimensional drawings, the greater the likelihood that a product can proceed to the development phase with unnoticed, undesirable features or design flaws that will at minimum result in delays, and at worse require expensive tooling redesigns and remanufacture.

Figure 1 (Data from: John Krouse, Krouse Associates)

The Communications Power of Solid Object Printing

Development teams can build three-dimensional models to eliminate misinterpretation and to identify errors that could lead to costly downstream problems. But because traditional hand-carved models are expensive and typically take weeks to produce, the benefits of building enough models to perfect the design must constantly be weighed against the opportunity cost of delaying time-to-market.

- Solid object printing can alleviate the time constraint. A solid object printer is a device that quickly "prints" inexpensive three-dimensional models from 3D CAD data, in much the same way that a desktop inkjet printer prints two-dimensional output from a word processor. In addition to dramatically reducing the modeling/time-to-market tradeoff, solid object printing lets development teams:

- Convey product concepts as quickly and thoroughly as possible. Instead of struggling to interpret drawings, people can hold a model in their hands, view it from different angles—and get an immediate and accurate representation of the product's shape and position of its features.

- Identify costly mistakes before proceeding to development. Anyone—from marketing staff to machinists—can quickly spot potential problems or undesirable features early, before it costs time and money to fix them.

- Win faster approvals. Decision-makers respond more quickly—and often more favorably—to physical models than to renderings, drawings, and text presentations.

- Impress customers and drive sales. Models elevate sales presentations and bid packages to a higher level, inspiring confidence that you can quickly deliver a finished product.

- Protect ideas. Solid object printing keeps your model making in-house—protecting your ideas at this critical early stage of development.

The largest manufacturing companies in the world adopted solid object printing early—and have reaped substantial time-to-market and profit rewards.

"What once would have taken months using conventional methods took just a couple of weeks," says Remi Renaud, supervisor of CAD/CAM Design at Ford Motor Company's Chassis Division. "Solid object printing saved us millions of dollars in manufacturing, paying for itself within the first three months versus conventional methods."

The Power to Iterate Is the Power to Innovate

Solid object printing has the potential to deliver more than improved communication between key functional groups. The faster and more accessible the solid object printing solution, the more flexibility to model multiple iterations and variations—thereby enabling you to develop higher quality, more innovative products in a shorter timeframe. Plus, as Wohlers notes, "Increasing the number of early iterations can dramatically reduce the design effort that occurs late in the design process."

3D Systems' ThermoJet solid object printer extends the maximum communication and innovation benefits of solid object printing to virtually everyone on the product development team. The ThermoJet printer makes it possible to:

- Build models in a few hours—at an average cost of $50 per model.

- Build directly from 3D CAD files. Just select the file(s) and click "Submit."

- Bring model making to any office. About the size of an office copier, the ThermoJet printer runs on standard electrical current, plugs into a standard outlet, and uses materials that are safe to handle.

- Put model making power on every desktop. Installed on a LAN, the ThermoJet printer lets you queue and manage multiple builds from multiple workstations.

Over a TCP/IP network, the ThermoJet printer also offers "3-D faxing," enabling a user to "print" an object from his or her workstation to a ThermoJet printer at another remote location. Within minutes, a user can "send" a three-dimensional model to anyone, anywhere in the world.

Another Communications Solution: Stereolithography

Stereolithography systems were available before solid object printers; as a result, many leading companies have used, and continue to use, stereolithography models to improve concept communication. While stereolithography systems have higher acquisition and operating costs than solid object printers, they build more detailed and more durable models—models that can be especially effective tools for winning approval from top level executives, key customers, and business partners.

Spencer Johnson of Logitech, a computer peripheral manufacturer that uses 3D Systems' SLA series stereolithography systems, describes one such case: "The total time from request for quote to finished prototype was seven working days. The model helped us clinch the business and beat a good competitor."

More important, many companies can justify the additional expense of stereolithography because it helps accelerate development in so many other ways, throughout the remaining phases of the development cycle. We'll examine some of those ways in the next article.

References

- Wohlers, Terry, Rapid Prototyping & Tooling State of the Industry, 1999 Worldwide Progress Report, p. 19.

- Ibid., p. 19.

- Based on a typical model, sized 5 x 6 x 3 in.

Michael Eneberg is product manager for 3D Systems, Valencia, CA. He can be reached at 661-295-5600, ext. 2205; Fax: 661-295-3404; E-mail: enebergm@3dsystems.com.

For more information, contact 3D Systems, 26081 Avenue Hall, Valencia, CA 91355-1241, USA. Tel: 661-295-5600 ext. 2882. Toll free: 888-337-9786. Fax: 661-294-8406. E-mail: moreinfo@3dsystems.com. Web site: http://www.3dsystems.com.