Medical Device Design & Development

INDUSTRY PERSPECTIVES

-

The Cybersecurity Void In Mexico: Why Your FDA-Compliant Device Might Still Fail

While Mexico's health authority, COFEPRIS, has streamlined registration for medical devices, a dangerous shadow regulation has emerged with ad hoc stringent cybersecurity requirements.

Stability studies measure how medical devices respond to environmental stresses such as temperature, humidity, light, and time. Let's take a closer look at designing and conducting a stability study.

Combining relational risk analysis (ReRA) modeling strategies with hazard analysis and critical control point (HACCP) and other process flow risk analysis methods makes them more efficient.

A shrinking FDA and rising supply pressures demand stronger risk management and smarter internal audits. Here’s how pharma can truly “see things as they really are.”

Over 25 years leading global quality and regulatory organizations, I've learned that the most difficult challenges aren't regulatory or technical; they're organizational and cultural.

WHITE PAPERS & CASE STUDIES

-

Deterministic Nondestructive Seal Integrity Testing

Deterministic, non-destructive seal integrity testing delivers validated, quantitative results. Learn why this method outperforms traditional approaches in ensuring patient safety and product quality.

Accurate PCD configuration ensures sterility assurance. Learn how to align validation strategies with ISO standards, optimize cycle efficiency, and select the right BI format for EO sterilization success.

New regulations challenged how surgical kits were tracked and processed across 15 U.S. sites. Discover how one team balanced compliance and efficiency to keep life-saving procedures on schedule.

Discover how a top medical device manufacturer accelerated product launch by digitizing assembly processes, streamlining training, and ensuring compliance.

A pioneering orthodontic startup is transforming custom aligner production using 3D printing and software to cut time and costs in half while scaling rapidly to ensure quality and compliance.

MEDICAL DEVICE DESIGN & DEVELOPMENT

Medical device design and development is the cyclical process of creating a device for a specific task or set of tasks, and then continuously reevaluating its effectiveness and improving upon it until the device reaches obsolescence. Design and development begins with ideation and the creation of a concept that, if found to be both fiscally and clinically viable, is then designed, engineered, and prototyped. This preclinical period includes bench testing — accomplished through simulated use of the product — and animal testing, along with any necessary redesign work.

Throughout the process, the proposed medical device, and the process by which it will be manufactured, is examined for flaws that may negatively impact the device’s safety, market viability, regulatory acceptance, customer satisfaction, usability, or profitability. Any shortcomings are corrected, and the improvements applied to the final design. Due to the wireless connectivity capabilities of many modern medical devices, cybersecurity and interoperability also must be incorporated into the design. Clinical testing is conducted, using human subjects, to further expose flaws and confirm product strengths. Once both the product design and the manufacturing process have been validated and approved by the U.S. Food and Drug Administration (FDA), production and commercialization of a device may begin.

LATEST HEADLINES

-

Strategy Beyond The Bench: Eurofins Launches New U.S. Consulting Chapter In Medtech Strategy & Policy2/19/2026

In launching this key offering, Eurofins Medical Device Consulting marks an inflection point for its Medical Device, Combination Product, and Diagnostic service portfolio – moving from testing services provider to full-lifecycle partner in strategy and insights.

-

Accumold Makes Pharmapack Europe Debut To Support Next-Generation Drug Delivery And Pharma Packaging1/15/2026

See how precision micro molding enables scalable, reliable drug delivery and pharmaceutical packaging designs as industry experts debut at Pharmapack Europe 2026 in Paris, January 21–22.

-

AbbVie To Buy Device Manufacturing Facility From West Pharmaceutical Services1/14/2026

The acquisition of the Tempe, Arizona facility will expand U.S.-based drug delivery device capacity and support the company’s $10 billion manufacturing investment.

-

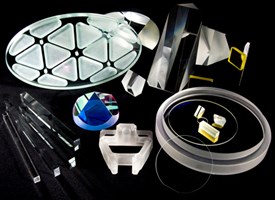

Accumold Brings Micro Molding Precision To Photonics West 2026 As Optical Innovation Accelerates1/13/2026

Accumold, a global leader in precision micro molding, will exhibit at SPIE Photonics West 2026 (January 20-22, San Francisco, USA), the premier event for lasers, biomedical optics, optoelectronics, and technologies supporting biophotonics, quantum, and vision applications.

-

Accumold Returns To MD&M West 2026 To Help Medical Oems De-Risk Miniaturization And Scale Micro Parts1/6/2026

Accumold returns to MD&M West 2026, Booth 2828, showcasing medical micro molding expertise, Design for Micro Molding guidance, and scalable, high-precision production for next-generation devices.

-

Accumold Showcasing Micro Molded Components Powering Optical Networking's Next Keap At OFC 20261/6/2026

Accumold will exhibit at OFC 2026, the premier event for optical networking and communications, from March 17–19 at the Los Angeles Convention Center.

-

Accumold Achieves ISO 13485 Recertification, Reaffirming Commitment To Precision In Medical Micro Molding11/24/2025

Accumold secures ISO 13485 recertification, reinforcing its commitment to precision, quality, and reliability in micro molded components for demanding medical device applications worldwide.

-

Accumold To Exhibit At Medevice Silicon Valley, Showcasing Micro Molding Expertise For Cutting-Edge Medtech11/11/2025

Accumold will showcase its world-leading micro molding expertise at MEDevice Silicon Valley, Booth #1034, helping medtech innovators accelerate design, de-risk production, and achieve micron-level precision.

-

Accumold To Showcase Micro Molding Innovation At COMPAMED 202511/1/2025

Discover Accumold’s micro molding expertise at COMPAMED 2025, where ultra-precision, scalability, and DfMM capabilities showcase how next-generation medical devices are enabled through unmatched miniaturization and manufacturing reliability.

-

Discover Medbio's Medical Molding Expertise At MEDevice Silicon Valley 202510/23/2025

Visit Medbio at Booth #941, November 19–20, to explore custom injection molding and assembly solutions, supporting Class I–III devices with quality, compliance, and MedTech innovation.