3D ADDITIVE WHITE PAPERS, CASE STUDIES, & APPLICATION NOTES

-

Sensor Fusion Enables Comprehensive Analysis Of Laser Processing In Additive Manufacturing

This white paper discusses sensor fusion, a process that merges data from numerous sensors to create a more complete understanding of the laser-enabled process.

-

Selecting The Right Material For 3D Printing

The materials used in 3D printing have improved to allow the technology to move beyond models and prototypes to functional parts for testing, shop floor use and production.

-

Sterilization Of 3D Printed Medical Devices

Fused Deposition Modeling™ (FDM® ) can be used to produce an array of medical devices; however, for such devices to be practical, they must be manufactured using sterilizable materials. By David Espalin, Francisco Medina, Mireya Perez, and Ryan Wicker, The University of Texas at El Paso; and Terry Hoppe and Rob Winker, Stratasys

3D ADDITIVE VIDEOS

-

Just because trade events and conferences are postponed and travel has been restricted, it doesn't mean that innovation has to slow down. Learn about the enabling power of micro injection molding from this Accumold Virtual Trade Show video.

-

This video gives insight on a dental medical device’s journey from the prototype phase to production. The device needed to be small enough to image rear teeth, robust enough to replace physical impressions, and had to make precision measurements for prosthetics. The process involved complex optics, steps to ensure hygienic sterilization, high resolution 3D imaging, and more. Download the video to see how it was done.

3D ADDITIVE PRODUCTS

-

Laser Measurement System For Laser-Based Additive Manufacturing: BeamWatch AM

Ophir's BeamWatch AM is an integrated laser measurement system for measuring critical laser beam parameters in laser-based additive manufacturing systems. Simultaneous, real-time measurements are performed at video rates and are available for multiple profiles along the beam caustic in the camera field-of-view.

3D ADDITIVE NEWS

-

Additive Manufacturing offers a series of benefits when combined with traditional manufacturing, such as rapid prototyping, superior geometric complexity and customization support, and more.

-

Micro 3D printing, also called micro additive manufacturing, produces printed parts at the micron level. Explore the advantages of micro 3D printing and how it compares to nano printing.

-

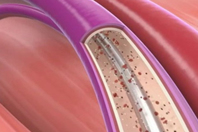

Thrombus accumulation on blood-contacting devices such as catheters, vascular stents, or hemodialyzers can lead to device failure or serious complications and has a significant impact on patient care, quality of life, and overall healthcare costs.

-

Selective Laser Sintering (SLS) systems use a high-powered laser to selectively melt and fuse powder particles of a bioresorbable polymer in a layer-by-layer 3D printing process to manufacture a final implantable medical device part. Depending on the part geometry, these systems can typically print geometries as small as 0.4 mm with a tolerance of +/- 0.25 mm.

-

Mold flow analysis is not required for the injection molding process. But maybe it should be, especially considering it can help to predict manufacturing issues before production starts.

-

Digital manufacturing uses technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and Machine Learning (ML) to connect services, supply chains, products, and processes. In doing so, it provides greater visibility into the entire supply chain.

-

Cost can influence nearly all aspects of your project, from material selection and surface finish to the types of features you include. When determining which technique to use at different points in the product development process, a cost comparison analysis can be helpful to provide a sense of when to start thinking about 3D printing or injection molding for your prototypes or production run.

-

These complementary processes can be adapted to serve countless prototyping and full-production demands, boosting medtechs’ bottom lines and speeding time to market.