MATERIALS WHITE PAPERS, APPLICATION NOTES, & CASE STUDIES

-

How Medical Technology Benefits From Piezoelectric Transducers

Discover the transformative potential of piezo technology in active microfluidics. Learn how unconventional drives redefine precision, efficiency, and innovation.

-

Best Practices For Molding Bioresorbable Materials For Medical Devices

Bioresorbable materials dissolve into the body, offering advanced medical device performance. Optimizing their manufacturing process is crucial for maximizing benefits beyond traditional implants.

-

The Standardization Of Plastic Luer Fittings

This white paper aims to explore the significance and challenges of the standardization of plastic luer fittings and the importance in ensuring the quality and safety of medical devices.

-

The Challenges Of Plastic Luer Fittings In The Medical Industry

The use of single-use plastic luer fittings in medical settings, medical devices, and patient care is an example where the sustainability versus safety debate arises. This white paper aims to explore this debate and offer insights into the challenges and opportunities that lie ahead.

-

Plastic Luer Fittings: A Cost-Effective Solution For Improved Efficiency

This paper aims to demonstrate the cost effectiveness of plastic luer fittings and how understanding the factors that contribute to their cost can help users select a cost-effective option that meets their performance requirements.

-

Build-To-Print Best Practices: Thin Film Technology And Process Guide

Thin film technology is the process of depositing a thin layer of material on a substrate. This guide provides an overview of thin film technology best practices.

-

CytexOrtho Advances Implant To Clinical Trials With Textile Design And Contract Manufacturing Solutions

After CytexOrtho developed a new implant to restore joints in young patients with early joint disease, they needed the support of an experienced, quality-driven CMO for the production of the implant, which required a highly specialized 3D-printing process, along with packaging and sterilization management.

-

Understanding Drawn Fiber: Polymers, Process, And Properties

Drawn fiber is an improved performance monofilament based on extrusion technology and found in a wide array of applications such as over-braiding for hoses, weaves as mist eliminators, medical braiding, instrument and racquet string, and strengthening for industrial belting applications.

MATERIALS VIDEOS

-

Designed to secure tubing over hose barbs effortlessly, Pharma+ retainers feature a revolutionary lead-in ramp ensuring complete 360° compression to prevent leaks.

-

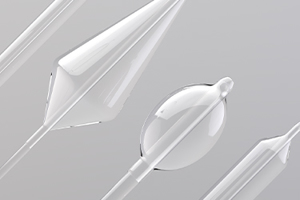

The latest innovation in sample switching technology, the Xover provides unprecedented carryover volume for fast, efficient fluidic performance.

-

Partner with Nordson for a complete solution to your catheter-based device needs. Our Catheter Center of Excellence, located in Galway, Ireland, offers a full range of in-house capabilities.

MATERIALS NEWS

-

After 5 years of work, Accumold has developed a high-volume micro injection molding method for thin-wall cannulas, replacing the expensive and less efficient extrusion process for medical device OEMs.

-

Craig Tappe, Sales Engineer at Accumold, highlights the micro molding process and emphasizes the significance of asking the right questions when selecting preferred suppliers.

-

Do soft/semi-hard tooling & CNC-machined cavities work for micro molding? Achieving small tolerances, sharp corners, and micro features remains challenging for both micro and larger parts.

-

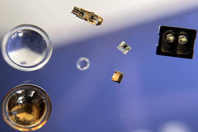

Micro-optics within the micro injection molding space require expert engineering and experience. Our resident micro optics engineer, Rick Brown, encounters the following common questions.

-

Thin film ceramic interposer design offers several advantages in RF and microwave applications. Designers can expect reduced signal losses, more effective thermal management, and more opportunities to reduce component size.

-

Boomerang projects in micro molding, where customers' projects return to the manufacturer for rework or modifications, present challenges due to design changes, quality issues, material-related challenges, and poor communication.