MOLDING WHITE PAPERS, APPLICATION NOTES, & CASE STUDIES

-

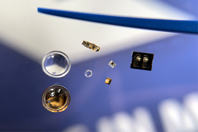

A Single-Source Partner For 5-Component Device

Go inside the story of a customer who needed a single vendor who could qualify and manage the manufacturing of their diagnostic portable sensor, a breakthrough device fast-tracked by the FDA.

-

Understanding Complexities Of Bioabsorbable Materials Achieves Consistent IV Loss

Expertise in bioabsorbable materials led to success in a major medical device challenge through a tailored approach, equipment, and proven protocols.

-

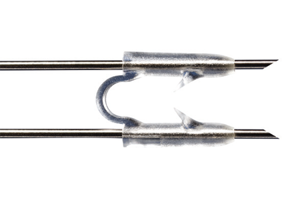

The Keys To Bioabsorbable Process Development

Learn how custom tooling, material characterization, and expert guidance improved the production of bioabsorbable fixation sutures for an OEM, resulting in reduced IV loss and consistent shot-to-shot quality.

-

The Advantages of Shotscope

ShotScope is a versatile tool not only for production scheduling but also for gauging required preventive maintenance, parts accounting, and operational efficiency.

-

Material Behavior At The Micro Scale: The Core Of Medical Device Innovation

Material behavior on the micro level is very different than what traditional (macro-level) plastics engineering has taught us. In this white paper, learn about polymer mechanics and how it might impact material selection for your micro medical device.

-

Comparing “Apples To Apples” With Your Med Device Injection Molding RFQ's

Navigating RFQs in medical device injection molding requires scrutiny beyond pricing. Explore crucial considerations for transparent partnerships and cost-effective solutions.

-

Micro Medical Manufacturing Tolerances

Precise miniature plastic parts are the result of exact tooling processes such as micro tooling and micro injection molding. By understanding the tolerances of these tooling processes, it’s possible to achieve repeatability and part accuracy for even the most advanced micro medical device.

-

Medtech Startup Gets To Market Faster With On-Demand Molding

Invoy Technologies, a Medtech startup, plans to release a novel handheld breath analyzer that instantly measures fat burning with a data-driven coaching app to help users reach their goals.

MOLDING VIDEOS, WEBINARS, AND PODCASTS

-

Discover unparalleled expertise in medical molding with Medbio. As a premier contract manufacturer, we offer comprehensive custom molding services, now enhanced through our partnership with Caplugs.

-

In this webinar, we delve into how conventional plastics behave under extreme shear stress and its real-world impact on micro medical product design. Gain insights to make informed material choices.

-

Utilizing Medbio’s Prototype-Plus process, the same tool that provides prototype samples for testing and validation can be used for the initial production run.

-

Take a look inside our ISO 13485 certified Orchard Park, New York locations featuring two full-service facilities: one dedicated to silicone and the other for thermoplastics injection molding.

-

Join us for a tour of the Medbio headquarters on our Grand Rapids campus, featuring multiple ISO 13485-certified facilities totaling 90,000 square feet.

-

Take a tour of Medbio's ISO13485 certified Clinton Township location's two facilities with approximately 55,000 sq. ft. of manufacturing space which house injection molding, in-house mold design, and tooling construction.

MOLDING NEWS

-

Explore the pivotal role of micro molding in driving innovation in micro-optics applications like medical devices and AR glasses, and why expertise, precision, and collaboration are key to success.

-

Micro molding innovations are revolutionizing biomedical device manufacturing with precision and scalability. Learn how this technology is shaping the future of patient care and medical advancements.

-

Navigating the intricate realm of micro molding demands precision at every stage. Explore the critical practices ensuring tolerance margins are met in this multifaceted process.

-

In biotech and medtech engineering, creating scalable strategies is crucial. Foreseeing challenges and fostering adaptable procedures are key to success in the face of rapidly expanding markets.

-

When faced with "no-quote" responses in micro molding, engineers should rethink assumptions and collaborate with Accumold's innovation lab for transformative solutions.

-

As you delve into micro injection molding, aligning with a proficient subcontract manufacturer proves essential for seamless product development, from conception to high-volume production.

-

Explore the future of micro manufacturing, where the convergence of micro molding and 3D printing promises to redefine what's possible in the creation of intricate, high-quality components.

-

Learn how the critical properties of micro molded components - such as strength, flexibility, and thermal resistance - are shaped by the intricacies of material selection.