Biodegradable Metal Implants Could Cut Costs Of Secondary Surgeries

By Joel Lindsey

Researchers at New Zealand’s University of Canterbury and Otago University are working to create biodegradable metal plates and screws that could be used in surgeries and to heal bone fractures — without the need for follow-up operations to remove the hardware.

“During its lifetime, an implant that is intended to temporarily assist the healing of a bone will transition from an implant to a foreign body, once the body has healed itself,” Mark Staiger, a professor of mechanical engineering at the University of Canterbury involved with the project, said in a news article published recently by The New Zealand Herald. “A major driver of this research is the cost-effective removal of this foreign body by having it biodegrade after having completed its role in bone healing.”

The main focus of this new research project is to create a magnesium-based metal alloy that could be safely absorbed back into the body after facilitating the bone healing process. This would eliminate the need for additional surgeries to remove plates, potentially making this approach to bone healing therapy more effective and less expensive.

“World-wide the total costs [of plate removal surgeries] are staggering,” said Staiger. “A temporary biodegradable implant would eliminate the need for surgical removal of the implant. Our previous work on the breaking down of magnesium alloys has shown their potential as a new degradable implant material.”

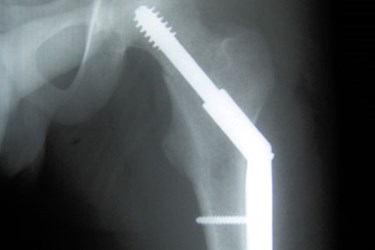

Titanium has become one of the go-to materials for use in plates and screws designed to help heal bone fractures, but researchers involved with this new project highlight the costliness of follow-up operations to remove hardware once healing is complete.

They also say that metals like titanium can be too inflexible and can lead to problems such as growth restriction, bone resorption due to stress shielding, and infection, according to The New Zealand Herald.

“Rigid titanium-based plates or screws have gained widespread acceptance in correcting head deformities and in the management of fractures in the last two decades,” said Staiger. “We are developing degradable magnesium plates and screws that will improve hospital costs and patient outcomes, representing a paradigm shift in the current technology.”

“This new approach will deliver reduced patient recovery time by enhancing new bone formation and reduce cost by eliminating the need for secondary surgery to remove implants,” he said.

Staiger and others involved with the project hope to begin working with medical device manufacturers in order to move the project closer to creating usable implants.

Image Credit: Cdm Hip Implant. Booyabazooka. CC 2004 under GNU Free Documentation License.