Choosing A Partner For Micro-Molded, High-Precision, Silicone Implantable Parts

By Dennis Rector, Flexan

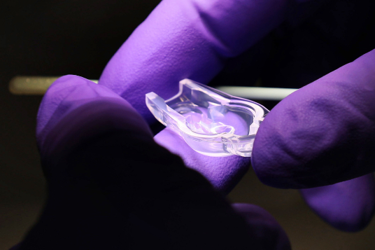

Silicone micro molding is a specialized silicone molding process utilized for parts and components requiring tight tolerances and high precision. While thermoplastic elastomer (TPE) and rubber also are utilized in micro molding, silicone typically is used for medical products — particularly implantable devices — due to its biocompatibility.

Micro molding is used for products that require tolerances within the micron range (i.e., ~1/1,000 inch), including components in minimally invasive surgical tools, valves, seals, and over-molding, as well as microsensory and microfluidics products. Additional medical applications include parts for pacemakers and pain management devices, as well as suture leads and anchors.

While numerous molders offer micro-molding services, Flexan is differentiated by its medical industry specific experience and expertise; specialized equipment to produce silicone, rubber, and TPE components within demanding tolerances; and technical competency to help clients through the design and production of existing, redesigned, and novel parts.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.