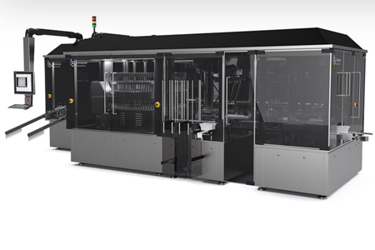

CVT Nest

Source: Stevanato Group

Our CVT inspection machine for syringes has been designed to process valuable drugs at an unparalleled speed, reaching up to 39,600 inspected units per hour. Thanks to its patented imaging technology, it provides reliable inspection results on difficult products such as foaming liquids, suspensions and viscous/gel-like products.

- Container range: syringes

- Container ø: 6-20mm, h=30-130mmm

- Inspected products: water-like, viscous, suspensions

- Speed: up to 39,600 units/hour

Available inspections

- Particle inspection

- Cosmetic inspection

- Fill level

- Closure integrity (integrated HVLD or HGA module)

- Cap/needle inspection, flange and plunger controls

Main features

- Sustained inspection capacity up to 39,600/h

- Short format change-over time including format dependent index positions

- Flexible integration to non-glass contact line handling systems including integration of batch data from line handling systems

- Individual rotation units to ensure proper re-homogenization of suspensions

- Pre-inspection of needle cap and flange to maintain high uptime

- Can accommodate a pre-spinning carousel with intermediate buffer to efficiently handle bubble-prone products

- 100% reconciliation for quality assurance

- Automated re-circulation of ejected syringes

- Freely configurable outlets for maximum production flexibility

CVT NEST

A 3-in1 system that combines the high performance CVT Automatic Vision Inspection machine with the Nestor De-nester and Re-nester units for a turnkey solution. This extremely compact system comes in 2 different combinations:

- CVT Nest Compact: minimizes footprint to facilitate operator intervention

- CVT Nest Flex: an inline solution for flexible integration of any kind of ancillary device: De-Nest + CVT + Printer / Labeling / Engraving + Re-Nest

This website uses cookies to ensure you get the best experience on our website. Learn more