Design Firm Helps Bring New MRI to Life

New system incorporates a more patient-friendly design

Many people have been inside a whole-body, high-field magnetic resonance imaging (MRI) system at some point in their lives. There is no question that the medical benefits of the technology have been far-reaching, but, at the same time, the patient experience has left something to be desired.

Hitachi Medical Systems America Inc. (HMSA; Twinsburg, OH) recognized this when they launched development of their next-generation high-field MRI—Celeris—in early 1999. The company made a strategic decision to not only to push the technology envelope with the new product, but also to make it significantly more patient friendly than existing models.

To achieve this, they engaged the services of Colorado MEDtech (CMED; Boulder, CO), a provider of contract outsourcing services to the medical device industry. Through CMED, Hitachi also employed Volan Design (Boulder, CO), an international product design and development company, with experience designing products for many market sectors, including medical. Volan Design handled all of the industrial design for the Celeris MRI, as well as engineering of the system's external components.

"Hitachi's primary goal for the project was to distinguish the company's new Celeris offering in the competitive, high-field MRI marketplace. They already own the leadership position in the open MRI arena, and were anxious to leverage that with their advanced high-field entry," explains Volan Design Principal Greg Volan. "Together with Colorado MEDtech, they recognized the important role that design would play in achieving differentiation and product acceptance."

Design Goals

One of the main design objectives was to make the patient experience as comfortable and non-threatening as possible. "Anyone who has been inside a full-body MRI knows how critically important it is to minimize patient discomfort," says Volan Design's director of design Bill Stephens.

In addition, the team wanted to streamline the MRI technologist's job, making system operation as easy and intuitive as possible.

Close-up of the Celeris MRI instrument panel.

Other key design goals included minimizing the perception of product size; decreasing overall part cost and complexity; and simplifying the assembly and ongoing maintenance of the sophisticated system.

Interior Improvements

Volan Design pioneered a number of innovations in the Celeris design. To enhance patient comfort, designers concentrated on making improvements to the interior of the central MRI tube (or "bore"). These included installing an embedded custom fiber optic cable (created using unique, large-core optical fibers) along the length of the bore, provided to generate subtle interior lighting.

Designers also added an adjustable ventilation system, powered by a variable speed fan.

Finally, Volan Design incorporated a two-way communications system into the Celeris, allowing the patient and operator to speak freely to one another, regardless of actual operator location.

Exterior Innovations

Innovations to the exterior of the MRI structure were dramatic. Volan Design sought to create a distinctive, contemporary aesthetic for the Celeris, which the designers achieved by breaking up the product's surface mass through the use of different shapes and colors. The creation of smaller side panels for easier service access also reinforced the desired visual effect.

Volan Design engineers worked closely with the industrial design team to ensure that the product's plastic reinforced fiberglass "skins" were wrapped as tightly as possible around the magnet, once again to minimize the perception of product mass. This process was particularly complex because, in addition to aesthetic concerns, engineering had to ensure that proper fit and function requirements were being met.

Another important design element involved the decision to "chamfer" or flare both ends of the bore, thus opening it up and easing the transition—both visually and physically—into and out of the MRI. The Celeris has one of the shortest bores in the industry, which makes the MRI more comfortable and less stressful for patients.

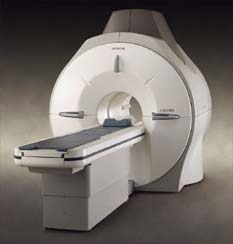

The Celeris MRI system from Hitachi Medical Systems America Inc.

was designed to be more patient friendly.

To simplify the task of system operation, Volan Design concentrated on creating ergonomically appropriate, easy-to-use displays and controls. This involved the design of a membrane switch keypad with a single, smooth surface, rather than buttons. The designers opted to mount two identical control panels on either side of the bore, for added convenience and flexibility of operations. The elimination of buttons on the control panel also reduced the parts count, as well as associated assembly complexity.

Reduced Time-To-Market

The engineers and industrial designers at Volan Design worked together on the Celeris design project from the start, in conjunction with Colorado MEDtech and Hitachi engineers. This concurrent product development approach resulted in a notable decrease in the time to delivery. From initial industrial design concept to delivery of manufactured prototype, the process took only 10 weeks—an unprecedented achievement, particularly for such a highly sophisticated product.

"Our concurrent development methodology allows us to iterate on the fly," explains Danny Estoque, project engineer for Volan Design. "We can be incredibly responsive and flexible, which makes a big difference, especially when working on a project of this scope. Plus, our use of leading software tools, like AliasStudio and Pro/ENGINEER, enables us to cycle through design iterations that much faster."

A Virtual Team

Greg Volan points to the way CELERIS was developed as an example of a strong emerging trend in industry today, that of the "virtual product development team." During the course of product development, Hitachi Medical Systems America worked closely with a number of vendors, including Colorado MEDtech, Volan Design, Intermagnetics (IGC), Hadlock Plastics, and Hitachi Medical counterparts in Japan, among others.

"This is the new model for the way in which products are being developed now," Volan says. "Typically the ultimate client—in this case Hitachi—defines and manages the project, selecting specific providers based upon their domain expertise, experience, responsiveness, and overall suitability. Virtual teaming—coming together for the life of the project—is the way of the future. Hitachi's approach to the development of Celeris was very cutting edge. The product's successful reception to date essentially serves as proof of method."

For more information:

Volan Design LLC

Greg Volan, 303/530-2828

greg@volan.com

www.volan.com

Colorado MEDtech Inc.

Chris Cone, 303/447-8750, ext. 107

Hitachi Medical Systems America

Shawn Etheridge, 800/800-3106, ext. 2675