Developing The Right Low-Pressure Balloons For Medical Device Applications

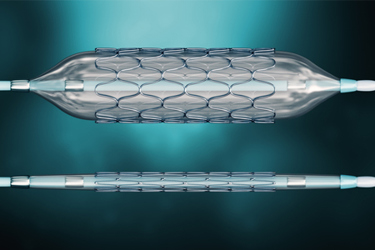

Medical device manufacturers have a wide range of methods and materials at their disposal when designing low-pressure medical balloons for applications such as gastrointestinal procedures, cardiovascular interventions, and targeted drug delivery. Among the most reliable and repeatable fabrication techniques are thermoforming and dip molding. These methods have proven effective in producing high-quality balloon components that can be precisely tailored to meet specific performance requirements. To ensure that these polymer-based components meet stringent performance standards, device manufacturers need to collaborate with experienced medical balloon specialists. Such partnerships help align the choice of materials with the most suitable manufacturing processes, ultimately enhancing the functionality and reliability of the final product.

Explore how this strategic alignment not only supports regulatory compliance and product consistency but also plays a vital role in improving patient outcomes by ensuring that the devices perform as intended in real-world medical environments.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.