Hazmat Regulations: What Life Sciences Companies Need To Know

By Susan Ritter, principal packaging engineer, Adept Packaging

Hazardous materials regulations are complex, but it’s helpful to remember the goal: It’s all about safety — safety for workers, consumers, and the environment. Most of the regulations are laid out in the U.S. Department of Transportation’s (DOT) 49 CFR Parts 100-185, which cover domestic shipment of hazardous materials. The regulations include package design and testing requirements, training requirements, and instructions on how to package and handle hazardous materials in bulk and non-bulk forms.

It is especially important for brands in the life sciences industry to understand these regulations and their impact on business. Pharmaceuticals, combination products, and gene therapy products may contain hazardous materials and require compliance. Both manufacturing materials and commercial drug products should be considered when reviewing these regulations to determine the best way to package and handle potentially hazardous items. It’s critical to determine early in a project if hazardous material is involved and to make sure that hazardous material packaging and testing activities, and the associated durations, are included in the project plan. For example:

- Pharmaceuticals and biologics may contain hazardous material, requiring compliant packaging and testing for both the drug substance and commercial drug product forms.

- Gene therapy manufacturing materials and drug products may contain hazardous biological substances. Shipment of these products typically requires the material to be maintained at frozen temperatures. Dry ice, classified as a hazardous material, is commonly used for temperature control in shipment.

- Combination products that include a drug and delivery device can also contain hazardous materials.

It is crucial to get things right the first time when it comes to packaging hazardous materials. In addition to the aforementioned safety risks, noncompliance with hazmat regulations can result in astronomical fines. Depending on the severity of the offense, these fines can range from $250 to $500,000 per violation.

All of these regulations and requirements are explained clearly in 49 CFR, but the real challenge comes in navigating the extensive text. Knowing where to look for the information most relevant to packaging can remove a lot of the headache from planning for hazmat packaging.

Most Relevant Sections

Sorting through 49 CFR’s 700-plus pages can be a time-consuming task if you don’t know what you’re looking for. It’s packed with information for dealing with all aspects of hazardous materials, but there are a handful of specific sections that contain most of the relevant information about packaging and shipping. In most cases, a packaging professional can find the information they need in:

- Subchapter C, Part 171: General Information, Regulations, and Definitions

- Subchapter C, Part 173: Shippers – General Requirements for Shipments and Packagings

- Subchapter C, Part 178: Specifications for Packaging

Definitions And Responsibilities

A hazardous material is a substance or material that the Secretary of Transportation has determined can pose an unreasonable risk to health, safety, and property when transported in commerce. “Hazardous material” is a blanket term that covers hazardous substances, hazardous wastes, marine pollutants, elevated temperature materials, and other materials designated as hazardous in 49 CFR 172.101.

As a packaging professional, it is not your responsibility to determine if a material is hazardous. That responsibility falls on the manufacturer. If you suspect you’re dealing with a hazardous material, the first step is to reach out to the manufacturer to get the safety data sheet (SDS). Your responsibility, then, is to understand the information on the SDS and determine the packaging and testing requirements. For packaging professionals, the most relevant information is included in Section 14 of this form, which contains transport information:

- The proper shipping name used by the DOT

- Dangerous goods classification

- U.N. identification number

- Transportation information

Hazmat Classifications

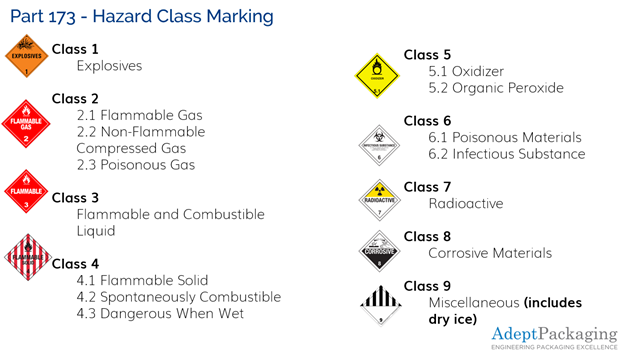

49 CFR categorizes hazardous materials in a few ways that inform procedures for packaging and shipping them. Each material covered by these regulations is categorized by a Hazard Class, Division Number, and Class Name. If the material doesn’t fit into those categories, it’s labeled as “other regulated material” by the letters “ORM-D.” A helpful guide to these categories is included below.

|

Class Number |

Division Number (if applicable) |

Name of Class or Division |

49 CFR Reference for Definition |

|

None |

|

Forbidden materials |

173.21 |

|

None |

|

Forbidden explosives |

173.54 |

|

1 |

1.1 |

Explosives (with a mass explosion hazard) |

173.50 |

|

1 |

1.2 |

Explosives (with a projection hazard |

173. |

|

1 |

1.3 |

Explosives (with predominately a fire hazard) |

173.50 |

|

1 |

1.4 |

Explosives (with no significant blast hazard) |

173.50 |

|

1 |

1.5 |

Very insensitive explosives; blasting agents |

173.50 |

|

1 |

1.6 |

Extremely Insensitive detonating substances |

173.50 |

|

2 |

2.1 |

Flammable gas |

173.115 |

|

2 |

2.2 |

Non-flammable compressed gas |

173.115 |

|

2 |

2.3 |

Poisonous gas |

173.115 |

|

3 |

|

Flammable and combustible liquid |

172.120 |

|

4 |

4.1 |

Flammable solid |

173.124 |

|

4 |

4.2 |

Spontaneously combustible material |

173.124 |

|

4 |

4.3 |

Dangerous when wet material |

173.124 |

|

5 |

5.1 |

Oxidizer |

173.127 |

|

5 |

5.2 |

Organic Peroxide |

173.128 |

|

6 |

6.1 |

Poisonous materials |

173.132 |

|

6 |

6.2 |

Infectious substance (Etiologic agent) |

173.134 |

|

7 |

|

Radioactive material |

173.403 |

|

8 |

|

Corrosive material |

173.136 |

|

9 |

|

Miscellaneous hazardous material |

173.140 |

|

None |

|

Other regulated material: ORM-D |

173.144 |

- Additional important information is found in the Hazardous Materials Table in 49 CFR §172.101, which:

- Designates the materials listed as hazardous for the purpose of transportation

- Identifies the hazard class or specifies that the material is forbidden in transportation

- Identifies the proper shipping name

- Provides U.N. identification numbers that apply to international regulations

- Specifies or references requirements pertaining to labeling, packaging, quantity limits aboard aircraft, and stowage of hazardous materials aboard vessels

Design Requirements

49 CFR §173.24 includes general requirements for packaging design ranging from the general, e.g., the packaging must prevent the release of hazardous materials into the environment, to the very specific, e.g., packaging used for frozen materials must also be capable of containing it in its liquid state if it melts. In fact, many of the testing requirements are centered on making sure packages won’t leak solids, liquids, or gases, and there are some very specific requirements, such as the conditions in which a package may vent to reduce internal pressure for packages containing dry ice (carbon dioxide, solid).

This section also includes information on closures, which must be leakproof and secured against loosening during transportation and storage. It outlines specific requirements for how closures on bottles containing hazardous liquids must be oriented, how labeling should indicate the orientation in which the package should be handled and stored (e.g., “this end up”), and how cushioning within the package should react in the event of an internal leak. It includes details about hazmat packages transported by aircraft, including closure procedures, absorption requirements in the event of a leak, and limits on quantities that can travel by air.

Testing Requirements

Package testing requirements are included in 49 CFR §178.601. Typically, all new packaging for hazardous materials must undergo a design qualification test, which should be completed at a hazmat-certified lab. The test report must contain specifications for all of the packaging components, along with very detailed assembly instructions that cover each step of the packaging process, up to and including closure specifications and how much tape to use.

Drop heights for the design specification tests are higher than you’ll typically see in package testing, including drops from 6 feet and higher. Also, unlike traditional testing, the hazmat lab is only looking at containment of the materials within the package, not if the items inside the package remain functional. Some types of packages will need to be periodically retested, and those requirements are also spelled out in 49 CFR §178.601.

Marking Requirements

49 CFR §178.3 focuses on markings for packages containing hazardous materials. These regulations express clear preference for direct printing on a package, rather than applying labels, because printing directly on the package is less likely to wear off. Like many labeling requirements, 49 CFR stipulates that marking must be in an unobstructed area and be clearly legible. It also establishes minimum sizes for all marking.

Arrows that indicate packaging orientation must be printed on two opposite vertical sides. The U.N. registration number issued when the package passes design qualification testing must also be printed clearly on the package. The U.N. registration number contains the year of manufacture, requiring annual updates to package markings.

The package must also bear the marking that reflects the hazard class of the material inside. Examples of those markings are included in the graphic below.

Other Regulatory Bodies

While 49 CFR contains the regulations and guidelines most relevant to shipment of hazardous materials within the U.S., there are other organizations that regulate hazardous materials in territories outside the U.S. These are helpful to be aware of if you’re shipping things to or from non-U.S. territories.

|

Location |

Regulatory Body |

Regulations |

|

International water |

International Maritime Organization (IMO) |

International Maritime Dangerous Goods Code, 38th Amendment |

|

International air |

International Civil Aviation Organization (ICAO) |

2017 – 2018, Technical Instructions for the Safe Transport of Dangerous Goods by Air |

|

International |

United Nations Committee of Experts, Sub-Committee on the Transport of Dangerous Goods |

UN Model Regulations, 19th Edition |

|

Canada |

Transport Canada |

|

|

Mexico |

Mexican Secretariat of Communications and Transportation |

|

|

Europe – Ground |

United Nations ECE |

International Carriage of Dangerous Goods by Road (ADR) |

|

Europe – Rail |

RID Committee of Experts |

Regulations Concerning the International Carriage of Dangerous Goods by Rail (RID) |

By necessity, hazardous material regulation is complex and strenuous. Getting things wrong can pose a significant safety risk, depending on the material, and the regulatory penalties for getting it wrong reflect this.

About The Author:

Susan Ritter is a principal packaging engineer at Adept Packaging, which delivers best-in-class engineering, consulting, talent and digital solutions for the packaging world. She has more than 35 years’ experience in project leadership for medical device, electronic hardware, and pharmaceutical package engineering.