Inspection Technologies

With an extended portfolio and a wide expertise in advanced inspection technologies, we can deliver flexible inspection solutions at any stage of the product journey; from lab development to high volume production.

Drawing on our experience for tailor-made inspection solutions

As a trusted and reliable partner for pharmaceutical companies all over the world, we work hard to understand your business goals and are committed to provide professional project management, reducing total cost of ownership and ensuring the highest drug integrity.

Inspection technologies

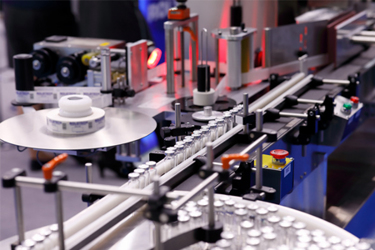

Through our Optrel and InnoScan brands, we provide inspection solutions for ampoules, vials, cartridges, syringes or bottles, filled with clear or opaque liquids, emulsions, viscous gels, lyophilized products and other difficult-to-inspect solutions.

Whatever the task - particle and cosmetic inspection or leakage testing - we provide the right inspection technology for any product.

A visual inspection equipment tailored to your needs

Explore our inspection machines

From manual units to high-speed fully automatic equipment, our portfolio covers a wide range of primary containers filled with drugs for various therapeutic areas.

- Manual Equipment

A multifunctional analysis equipment for a smooth transition from laboratory to mass production - Semi-automatic equipment

These semi-automatic inspection machines can ease the operators’ daily activities, ensuring accurate inspection - Automatic Equipment

For pharmaceutical products contained in syringes, ampoules, vials, cartridges and bottles

More than 30 years of inspection experience

- Maximum Flexibility

- Regardless of the drug or container, we develop the optimal inspection solution for each customer. We provide flexibility through freely configurable infeed, outfeed and item classifications.

- Highest Inspection Quality

- Optimal synchronization of high performance CMOS cameras, illumination and container rotation enables highly efficient, multi-inspection of each primary container.

- Low False Reject Rates

- By applying the best-suited inspection technologies and through the pioneering use of Artificial Intelligence, we can further reduce false reject rates.

- Smooth Mechanical Handling

- Gentle handling and transport of containers prevent scratches and reduces the risk of glass breakage and product loss.

- Easy and quick format change

- All format parts are clearly marked and numbered and can be changed quickly and without any tools, thus increasing overall equipment effectiveness.