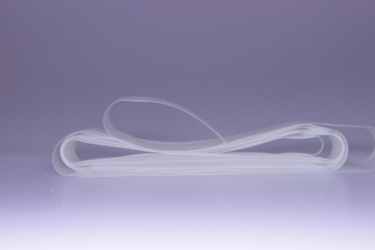

Lay Flat Tubing

Applications for lay-flat tubing are extensive. In the medical realm, this process can be utilized to construct sheathes to be used as barriers for colonoscopes, endoscopes, speculums, probes, and many other devices requiring protection from moisture, blood, or bacteria. These sleeves can provide a cost advantage over current practice of extensive cleaning or reprocessing.

LAY FLAT EXTRUSION PROCESS

Blown film extrusion is a process that uses a circular die and create a “bubble” with heat and air. Polyzen does this on a small diameter die. Capabilities include but are not limited to, producing thin-wall tubing with a thickness ranging from 0.0005″ – 0.010″ with a tolerance of +/- 10% of thickness. The small-diameter lay-flat tubing can be extruded at a width ranging from 0.3″ – 2.5″ (lay-flat width). All extrusions are done within a class-10,000 clean room environment.

MEDICAL LAY FLAT TUBING MATERIALS

Polyzen’s custom tube manufacturing capabilities allow for the use of many standard and custom polymer formulations. Examples include thermoplastic polyurethanes (TPUs), thermoplastic elastomers (TPEs), polyamides (nylons, Pebax*), ethylene vinyl acetates (EVAs), polyvinylidene fluoride (PVDF), polypropylene, and polyethylene. Our in-house compounding capabilities allow us to enhance properties of these polymers with radiopaque fillers, custom colors, stabilizers, and more.

MEDICAL FILM EXTRUSION TECHNOLOGIES

Partner with Polyzen to develop medical films from nearly any extrudable polymer. Custom films bring a multitude of beneficial properties and characteristics to medical innovations, including flexibility, durability, smaller profiles, and biocompatibility.

Explore how you can leverage medical films to integrate applied biomaterials solutions into your vascular, surgical, and orthopedic medical innovations.