Making Medical 3D Printing Faster And More Precise With Piezo Technology

3D printing has quickly become established within the medical field and enables therapies that were unimaginable just a few decades ago.

However, the advances made in medical technology have been accompanied by an increase in the requirements placed on medical devices, implants, prosthetics, and components. Geometries and structures are becoming more complex, and fast, precise manufacturing, e.g., of personalized implants, is required.

Some 3D printing processes can profit from piezo technology. In medical technology, this includes material or binder jetting. Piezo actuators are preferred in both of these processes because their high speed makes them ideal for creating extremely precise droplets.

Jetting, here, is the process of creating droplets in print heads, e.g., in 3D printing systems. A wide range of piezo elements or actuators apply force pulses to the microfluidic channels in the print head so that the extremely fine droplets – with sizes in the microliter range – land contact-free on the printing substrate.

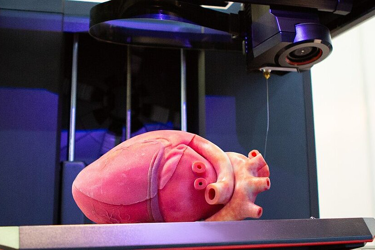

In the so-called material jetting process, fluid polymers can be printed with a variety of material properties or colors. These methods are used, for instance, to create patient-specific organ models for operation planning.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.