Manufacturing Transfers: How Flexan Helped An OEM Deliver 140+ Precision Medical Devices Without Missing A Deadline

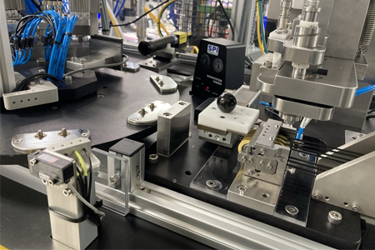

Flexan recently executed a high-stakes manufacturing transfer for a top-30 medical device manufacturer, relocating the production of over 140 custom Class-III silicone components to their facilities. This “Lift and Shift” project required Flexan to meticulously replicate the OEM’s original operations, from equipment and software validation to transferring and validating over 200 molds and 20 unique pieces of equipment. Despite the project's complexity and tight timeline, Flexan maintained supply chain continuity, avoided disruptions, and met all deadlines.

Leveraging their 75 years of experience, Flexan employed a rigorous 7-step phase-gate project plan with integrated quality assurance to identify and address potential issues early. Their proven track record in managing large-scale manufacturing transfers made them the ideal partner to ensure seamless production continuity and adherence to stringent quality standards.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.