Medical Device Design: The Benefits Of Partnering Early With An Expert Textile Supplier

Medical textiles are critical components of implantable medical devices. Whether they’re designed for cardiovascular, general surgery, orthopedic, or neurovascular applications, implantable medical devices rely on many components that work together synchronously to enable and enhance patient quality of life. How do medical textiles fit into the big picture?

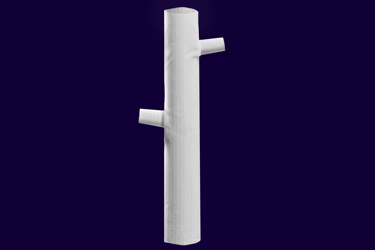

Medical textiles have many diverse applications. They’re typically used as flexible scaffolds or structures for tissue in-growth and implant integration, conduits or barriers for blood flow, and as a way to join materials and secure implants in the body. They’re also used for tissue reinforcement and wound support, joint support, and retrieving blood clots or preventing or reducing plaque debris in neurovascular applications.

One of the biggest challenges medical device engineers face during the design phase is selecting the right fabric materials and structures for a medical device, regardless of application. Ideally, device engineers should partner with a textile component supplier as soon as possible during the earliest stages of product development to optimize device design and avoid downstream biocompatibility issues. But how can a device manufacturer pinpoint the right textile partner?

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.