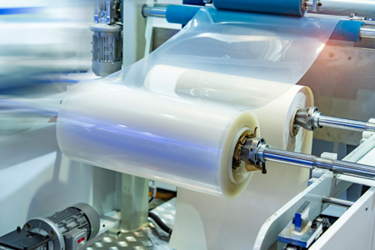

Medical Polymer Films And Laminates

Polyzen is an innovative developer and manufacturer of polymer films, membranes, and laminates for a broad range of medical and non-medical applications. We specialize in single and multilayer extruded films in various sizes, thicknesses, and material formulations. Our in-house film extrusion capabilities include material formulation, film prototyping, film production, testing, inspection, validation, assembly, and logistics management. Combined with our extensive knowledge of medical device quality and regulation standards, Polyzen has become a trusted film supplier to medical device OEMs worldwide.

MEDICAL FILM APPLICATIONS

We are dedicated to helping our customers deliver better quality products that positively impact the lives of other through innovation, collaboration, and customer service.

MEDICAL POLYMER FILM MATERIALS

Polyzen is capable of producing films, membranes, and laminates from an array of materials. Options include thermoplastic polyurethanes (TPUs), thermoplastic elastomers (TPEs), polyamides (nylons, Pebax®), polyesters (Hytrel®, Arnitel®), ethylene vinyl acetate (EVA), polyvinylidene fluoride (PVDF), polypropylene, polyethylene, bio-absorbable polymers, and more. Multi-layer films using these and other materials are also available. Lamination can also accommodate PSA’s, Non-woven & Coated Fabrics.

EXTRUSION PROCESSING CAPABILITIE

- Mono-layer or Multi-layer Constructions

- Co-Extrusion (A:B or A:B:A)

- Width Range:4″ – 48″ (In-line slitting abilities)

- Gauge/Thickness: 0.0005″ – 0.060″

- Finishes: Gloss or Matte

- Testing: In-line gauge measurement system

- Facilities: Clean Room Manufacturing

LAMINATION PROCESSING CAPABILITIES

- Barrier Films

- Lamination of Polymer to Fabric

- Multi-layer Film Constructions

- Width Range: Up to 48″

- Gauge/Thickness: 0.0005″ – 0.060″

- Finishes: Gloss or Matte

- Testing: Tension control/web handling

- Temperature profile – up to 550F

- Process speeds as low as 1ft/min

- Facilities: Class 10000 Clean Room Manufacturing

MEDICAL FILM EXTRUSION TECHNOLOGIES

Partner with Polyzen to develop medical films from nearly any extrudable polymer. Custom films bring a multitude of beneficial properties and characteristics to medical innovations, including flexibility, durability, smaller profiles, and biocompatibility.

Explore how you can leverage medical films to integrate applied biomaterials solutions into your vascular, surgical, and orthopedic medical innovations.

PURCHASE POLYZEN FILMS ONLINE TODAY

Polyzen has partnered with Chamfr Marketplace to offer our thermoplastic extruded films online to allow engineers to prototype faster. Order online today samples of our medical-grade films – which are in-stock and ready to ship within 24 hours.