New Bioink Can 3D Print Tissue At Room Temperature

Advances in 3D-printed biomaterials have been limited by the chemical processes and high printing temperatures required by their bio-inks. Researchers at Tufts University, longtime proponents of the biomedical potential of silk, have introduced a silk-based bio-ink that they say can be printed at room temperature without any harsh chemical treatments. The unique properties of the silk, they told the American Chemical Society (ACS), will pave the way for a host of more complex 3D-printed tissues loaded with biologic drugs or stem cells.

3D printing has thus far made liberal use of materials like silicone, thermoplastics, collagen, gelatin, or alginate, but all these materials require high temperatures to set up and to retain their structures. Their curing process often involves chemicals or a change in PH balance, which can break down biologic components infused in their ink. Scientists have long-believed that they could create a 3D-printed replica of a human organ suitable for transplant by using 3D printing methods and stem cells, but they’ve lacked a suitable ink.

In 2011, Fiorenzo Omenetto, a biomedical engineer at Tufts University, gave a Ted Talk in which he touted new research on a material that’s been around for a few millennia. Silk, he said, was sustainable, easy to process, biodegradable, and caused no immune response when implanted. Because silk-based materials are primarily water and protein, they show an extraordinary capability to self-assemble and self-cure.

In his speech, Omenetto referenced David Kaplan, who he said pioneered silk research and has been diligently working to explore its possibilities for the past two decades. In a study published in ACS Biomaterials Science & Engineering, Kaplan and his team introduced a two-part formulation for silk-based bio-ink that could print both 2D and 3D, and cure itself at room temperature.

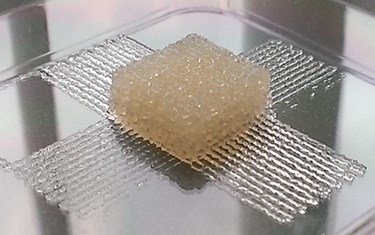

Their ink is made from silk proteins and glycerol, a non-toxic sugar alcohol. When printed, the substance is clear, flexible, and stable in water without requiring any additional chemicals to maintain its structure. Study authors noted that these unique properties “provide useful options for biofunctionalization and a broad range of applications.”

In June, a Tufts team lead by Omenetto announced they’d developed a silk-based bioink to print bacteria tests onto latex gloves, which would spell out the word “contaminated” if the gloves came into contact with E.coli. David Kaplan spoke on All Things Considered about the possibility of silk-screws for orthopedic repairs, which could deliver drugs and dissolve once the fracture had healed.

Earlier this year, Tufts researchers grew brain tissue on silk and collagen, and then kept it alive for months of study in the lab. For two months, researchers at the Tissue Engineering Research Center (TERC) at Tufts were able to experiment with and study traumatic brain injury.

Rosemarie Hunziker, director of tissue engineering and regenerative medicine for the National Institutes of Health (NIH), told Phys.Org, “We don’t have any other center focused in this way. The number of developments that have come out of [TERC] over the years is dizzying.”