Novel Polymer Could Be Used To Build Artificial Muscles For Next-Generation Prosthetics

Researchers are investigating a plastic used in filters and tubing for a number of new applications, because of its ability to produce electricity when pulled or pressed. They believe that by adapting the polymer they could create artificial muscles that expand or contract in response to electric current or temperature changes.

A team of scientists from the University of Texas at Dallas (UT Dallas) recently discussed the potential of polyvinylidene fluoride (PVDF) at the 249th National Meeting & Exposition of the American Chemical Society (ACS).

Last year, Med Device Online reported that PVDF was a popular choice for marking reusable medical devices in compliance with the FDA’s Unique Device Identifier mandate. Because PVDF resists solvents and acids, and demonstrates excellent durability and biocompatibility, it is particularly suited to coating devices that must undergo routine sterilization.

Due to PVDF’s unique properties, the material has also made its way into electronic applications such as pressure sensors and tilt sensors. However, the UT Dallas team believes that PVDF’s full potential is yet to be realized.

“If we produce it under precise conditions, we can make it piezoelectric, which means if I stretch it, it generates electricity,” Walter Voit, an assistant professor of mechanical engineering at UT Dallas, said in an ACS press release. “Or I can put electricity onto the surface of the material and make it change shape.”

By controlling its production and making adjustments to boost its piezoelectric properties, Voit believes that the material could be put to much more sophisticated uses.

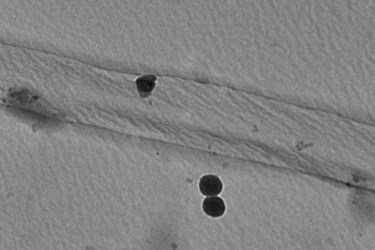

The team found that they could double the piezoelectric performance and strengthen the electric field of PVDF by incorporating buckyballs and carbon nanotubes into the material’s fibers. By combining PVDF with carbon, Voit believes that his team has created the best piezoelectric composites currently in development.

To make the material powerful enough for use artificial muscles, the team believes that PVDF-carbon hybrid could be coiled. In an experiment conducted in Voit’s lab with nylon fibers, they found that a coil of nylon could contract by 50 percent and lift 16 pounds when heated.

“The effect is similar to twisting a rubber band. If you pull on it when it’s coiled, you get a lot more strain on the rubber band than if it’s just straight,” explained Voit in the press release. “We have to coil it. We have to have the right piezoelectric properties after it’s in that complex shape. That’s the real secret sauce that we think we can pull off.”

Voit continued by saying that producing synthetic muscles from his team’s new PVDF-carbon combination could make prosthetic limbs much more lifelike.

Image credit: Voit lab, UT Dallas