Spec It Right: Precision Tubing Run After Run

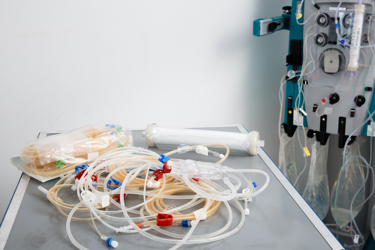

This precision medical tubing is manufactured using process-controlled extrusion and injection molding to meet the demanding requirements of medical devices and fluidic systems. The result is tubing with tight tolerances and uniform dimensions, ensuring consistent, repeatable results and dependable system performance.

The manufacturing process utilizes Broad Dimensional Control, from Micro to Multi-Millimeter. Extremely small tolerances are achieved using a two-axis laser for in-house extrusion and post-processing, keeping dimensions consistent. Typical ID/OD tolerances for current tubing can be as small as 25 um. Precise internal and external diameters are maintained using ultrasonic online gauging with real-time monitoring, ensuring the OD and ID remain on target and maintaining true wall thickness. The quality is built in and verified in the process. Real-time measurements validate every length of tubing, and Statistical Process Control (SPC) confirms the process stability. Available materials include ETFE, FEP, PEEK, PFA, and Ultem, with many available as high-temperature thermoplastics. This tubing is built to support innovation in advanced diagnostics, infusion systems, and surgical instruments.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.