ABOUT MEDBIO

At Medbio, we apply our knowledge, expertise, and cutting-edge technology to deliver products that improve the quality of life.

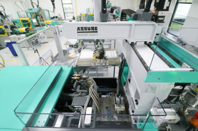

We are an ISO 13485:2016 certified, FDA Registered service contract manufacturer and custom molder for the medical and biotechnology industries. We specialize in precision injection molding, assembly, packaging, project management, and design support.

From concept and design to full production, our expertise is paired with the agility and passion needed to deliver solutions to your most complex manufacturing challenges.

We have numerous certified ISO Class 7& 8 cleanrooms and white rooms for molding and assembly. We have flexible capacity to handle major projects or small custom orders. We mold most medical grade thermoplastics, including implant grade “PEEK and all our silicone molding is done in its own facility.

Our facilities were designed and built specifically to meet the high standards of medical and biotech device manufacturing. We take pride in our best-in-class, agile manufacturing capabilities and our ability to customize process areas to meet your project requirements.

Now partnered with the global manufacturing excellence of Caplugs for a combined 100+ years of experience serving the medical market. Trusted by over 1,500 medical customers and the top 30 medical device manufacturers, we offer the most comprehensive range of medical contract manufacturing and custom molding solutions in the marketplace.

Learn More @ www.medbiollc.com

Take your Medical Device from Design to Completion

- Full–service contract manufacturing

- Comprehensive in-house custom molding capabilities across a range of molding processes, materials, tolerances, and complexities

- State-of-the-art tool rooms for shorter lead times and easier modifications

- Seamless tool transfer process to eliminate downtime delays

- Team of dedicated engineers to take your project from start to finish: Plastics Engineers, Mechanical Engineers, Electrical Engineers, and Biomedical Engineers

- Complemented by a standard offering of the medical industry’s commonly used protective parts and packaging, all in stock and ready to ship.

Engineered Solutions

Utilizing a collaborative approach, we determine the best molding process in order to deliver consistent solutions, while accommodating your budget and time constraints.

To mee your requirements, we employ our team of in-house engineers, embracing scientific molding principles to ensure the highest levels of quality and repeatability.

We recognize that flexibility and innovation are critical to your operations. Let our experienced team work with you one-on-one.

Full Service Medical Contract Manufacturer

- Product Development

- Project Management

- Precision Tool Design & Construction

- Cleanroom Precision Injection Molding

- Cleanroom Assembly & Packaging

- Laser and Ultrasonic Welding – Gluing/Solvent Bonding

- Pad Printing and Hot Stamping – Laser Etching

- Pouching, Tray Sealing, Bagging, and Shrink Wrapping

- White Room Molding

- Flexible Capacity

- Rapid Turnaround

- Prototyping

Medical Injection Molding

- Medical Grade Thermoplastics

- Silicone

- Two-Shot Molding

- Insert & Over Molding

- Micro Molding

- Thin-walled Parts/Coining

- Hand-loaded Cores to Full Automation

- Scientific Process Development (RMT)

- Kistler Cavity Pressure Sensors

- In-house Tooling

Quality and Metrology

- ISO 13485:2016 Certified

- Fully Capable Metrology lab

- Full Annual Internal Audit Schedule

- Quality programs tailored to suit individual requirements.

Qualification Capabilities

- Part Measurement

- Measurement Systems Analysis

- First Article Inspection

- Capability Studies

- Product Qualifications

- Fixture Qualifications

- Process Qualifications (IQ, OQ, PQ)

- Multi-run Validations

Industries

- Orthopedic

- Ophthalmology

- General Surgery

- Biotechnology

- Diagnostics

- Cell Growth

- Cardiovascular Surgery

- Neurological Surgery

- Wound Care

- Dental

- Respiratory

- Veterinary

CONTACT INFORMATION

Medbio

5346 36th Street SE

Grand Rapids, MI 49512

UNITED STATES

Phone: 616.245.0214

PRESS RELEASES

FEATURED ARTICLES AND DOWNLOADS

-

Medbio partnered with SBE Medical to refine and produce the Tibbe™, an innovative catheter designed by Mary Tibbe to eliminate issues like leakage and irritation for female patients.

-

Medbio's tool transfer process ensures seamless relocation of medical device manufacturing by assessing tools, implementing improvements, and rapidly resuming production to maintain quality and efficiency.

-

A full-service medical injection molding company should focus on what is necessary to help customers be highly successful by keeping them at the forefront of technology and in front of their competition.

-

Medbio specializes in the two-shot molding process, also sometimes referred to as "multi-shot molding," where a single tool can be used to mold a substrate and an overmold in a single molding cycle.

-

Insert molding and overmolding are commonly used interchangeably, and while they do have similarities, they also have distinct differences.

-

Medbio’s focus on quality extends from our molding teams into assembly and packaging. Our assembly team strictly follows the validated process to reduce part-to-part variation, and provides the quality our customers expect while packaging individual devices or kits.

-

There are many options when it comes to manufacturing plastic parts. Each process has it's pros and cons. Knowing your quantity goals, timelines, and budget are all important factors to take into consideration from the beginning.

-

Headquartered in West Michigan, Medbio is a contract manufacturer offering innovative manufacturing solutions for the medical and biotechnology industries. Medbio specializes in precision injection molding, assembly, and packaging.

-

MedBio provides three levels of validation. These segments allow you to quickly reference the degree of validation

that you need, and implement it as needed. This gives your team valuable time to focus on product design and commercialization. -

Precision injection molding ensures that, regardless of the annual production volumes, the process can be consistently repeatable. Learn the critical steps that need to be considered for success with an injection molding project in order to get the process right the first time.

-

Meeting the FDA regulations for medical device usage, medical grade silicone properties are inherently inert to bacteria, mold, and fungi.

-

MedBio provides design modifications and enhancements, tooling design, manufacturing automations, quality assurance, assemble, and packaging assistance. Their engineering team consists of plastic, mechanical, electrical, and biomedical engineers.

-

Injection molding has numerous key parameters that must tie together in order to make a repeatable molding process. Learn about a solution that utilizes cavity pressure curves, key process parameter tolerances, and automation to automatically reject parts that do not make the cut in the molding process.

VIDEOS

-

Discover unparalleled expertise in medical molding with Medbio. As a premier contract manufacturer, we offer comprehensive custom molding services, now enhanced through our partnership with Caplugs.

-

Utilizing Medbio’s Prototype-Plus process, the same tool that provides prototype samples for testing and validation can be used for the initial production run.

-

Take a look inside our ISO 13485 certified Orchard Park, New York locations featuring two full-service facilities: one dedicated to silicone and the other for thermoplastics injection molding.

-

Join us for a tour of the Medbio headquarters on our Grand Rapids campus, featuring multiple ISO 13485-certified facilities totaling 90,000 square feet.

-

Take a tour of Medbio's ISO13485 certified Clinton Township location's two facilities with approximately 55,000 sq. ft. of manufacturing space which house injection molding, in-house mold design, and tooling construction.