ABOUT US

PTI Inspection Systems PTI is a global leader in package testing equipment for the medical device and pharmaceutical industries. We offer inspection systems for package leak testing, seal integrity and container closure integrity testing (CCIT). Our technologies exclude subjectivity from package testing, and use test methods that conform to ASTM standards. PTI’s inspection technologies are deterministic quantitative test methods. We specialize in testing solutions for porous and non-porous pouches, Tyvek packaging, Tyvek pouches and Tyvek lidded trays. PTI offers the entire solution including test method consulting and equipment validation.

PTI offers two non-destructive technologies to inspect medical device packaging; vacuum decay and airborne ultrasound. Both technologies aim to offer quantitative and deterministic test results to evaluate package quality. The two technologies are vastly different in function and performance. Vacuum decay is focused on package integrity and detection of leak paths. Airborne ultrasound is focused on seal inspection and seal quality. Contact us to learn more.

CONTACT INFORMATION

PTI Packaging and Inspection Systems

8 Skyline Drive

Hawthorne, NY 10532

UNITED STATES

Phone: 914.337.2005

Fax: 914-337-8519

Contact: Michelle Wolf

[WEBINAR] THE SENSITIVITY TRAP: BUILDING CONFIDENCE IN CCIT PERFORMANCE

Wednesday, February 25, 2026, 11:00 am EDT

(8:00 AM PDT, 4:00 PM BST, 5:00 PM CEST)

Explore how to achieve reliable and defensible container closure testing results that truly reflects product integrity.

In CCIT, sensitivity is often treated as the ultimate benchmark of performance. However, sensitivity without repeatability, statistical confidence, and real-world relevance can increase risk rather than reduce it. True performance is the ability to reliably and defensibly differentiate intact from defective containers under defined conditions.

Key takeaways for attendees:

- What meaningful CCIT performance really means beyond micron claims

- Why higher sensitivity is not always better CCIT performance

- How to define a defensible LOD with confidence

- What auditors actually care about in CCIT studies

MASTER CCI TESTING: COMPLIMENTARY WORKSHOP AT PTI EUROPE

PTI invites you to a one-day, in-person CCI training program on Thursday, March 19, 2026, at our Europe Center of Excellence in St-Prex, Switzerland, designed to address current regulatory expectations and best practices.

What You’ll Experience:

- Comprehensive demonstrations of advanced CCI technologies

- In-depth training on Helium Leak Detection, Vacuum & Pressure Decay, and High Voltage Leak Detection (HVLD)

- Updates on current regulatory compliance expectations

- Interactive sessions with PTI’s expert team

- Networking opportunities with industry professionals

VIDEOS

-

Micron‑level defects can jeopardize autoinjector sterility. Learn how vacuum decay offers a deterministic, repeatable way to verify container integrity and strengthen quality assurance.

-

Deterministic CCI testing ensures compliance in packaging. Learn how advanced methods like Vacuum Decay, HVLD, and Helium Leak Detection deliver results aligned with USP 1207 and global standards.

-

Test multiple samples at once with a multi‑sample testing platform that ensures accurate detection for low headspace formats and integrates into automated lines for high-volume efficiency.

-

Discover comprehensive CCI solutions that help ensure compliance, reliability, and confidence in your processes. Strengthen your quality strategy with expert-driven services designed for life sciences.

-

Learn how to detect critical defects, reduce risk, and ensure compliance through flexible service options and data-driven testing that eliminates subjectivity in medical device packaging quality assurance.

WEBINARS

-

In this webinar you'll learn how to assess test method accuracy, information, and data analysis, how to carefully define method transfer objectives for each application, and more.

-

This video discusses the importance of protecting package contents from contaminants, including challenges associated with transport and specifically how altitude and latitude affect packaging formats.

-

This webinar takes a look at the pros and cons of manual visual inspection. Join us in taking a deeper dive into this probabilistic test method.

-

This short podcast focuses on experimental design and statistical tools we use with non-destructive package integrity test systems that produce reliable and robust quantitative test data.

CASE STUDIES

-

Cryogenic storage can compromise packaging integrity for cell and gene therapies. Learn how vacuum decay technology detects micro leaks and ensures product safety under extreme conditions.

-

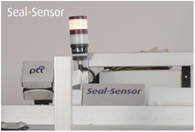

High product costs and superior quality requirements are the two single reasons for successful integration of airborne ultrasound seal inspection for medical device packaging. This case study focuses on the use of Seal-Scan® for final seal quality verification for an implantable sterilized medical device.

-

A nondestructive integrity-testing method will help an implant maker expand its testing program with little effort.

-

Medical device manufacturing is a labor intensive process, requiring operator involvement from manufacturing through final inspection of products. High product costs and superior quality requirements are two reasons for successful integration of airborne ultrasound seal inspection for medical device packaging. By PTI Inspection Systems

WHITE PAPERS

-

Deterministic Nondestructive Seal Integrity Testing12/18/2025

Deterministic, non-destructive seal integrity testing delivers validated, quantitative results. Learn why this method outperforms traditional approaches in ensuring patient safety and product quality.

-

Experimental Design And Positive Controls For Package Integrity4/9/2020

Given that the experimental design has only two conditions, leaking and non-leaking, this variable is extremely important to understand. Proper use of positive controls and knowledge of how alternative approaches are applied to challenge a test method support the validity and reliability of the method.

-

Container Closure Integrity Testing: Sensitivity, Automation, Efficiency4/6/2020

Explore the need for sensitive, reliable, and automated container closure integrity testing technologies, and how existing deterministic solutions can help achieve optimum quality assurance goals.

-

Dye Ingress For CCIT: A Poor Bet In A High Stakes Game3/23/2020

The dye ingress test method continues to be a widely used test method for container closure integrity. This paper explains why the dye ingress test method is not a suitable approach.

-

New Guidelines Offer Menu Of Standard Sterile Package Tests3/5/2019

High-risk packaging applications, such as pharmaceutical and class III medical devices, are coming under increasing scrutiny. A package protects the product throughout the product life cycle, and package integrity is a significant pocket of risk that can be mitigated.

-

Understanding Ultrasound Technology To Inspect Pouch Seals

Traditional test methods of testing pouch seals are often destructive and can be unreliable. However, ultrasound technology offers a non-destructive means to ensure pouches are airtight.

-

Flexible Insights

As more and more packages and processors convert to flexible packaging from more traditional forms of rigid methods including metal cans, PET and glass bottles or jars, they are confronted with the concern and challenge of how do they insure or equal the seal integrity levels from flexible packaging that they have come to expect from these more traditional packaging methods. Submitted by PTI Inspection Systems

-

How Important Is The Physical Integrity Of The Blister Package?

Untold millions of medicinal tablets and capsules are produced every year, and many of the over-the-counter varieties are encased in blister packs for protection. Existing manual methods for inspecting these packages are subjective and lack repeatability, while electronic techniques have to date been stymied by the great variation in blister packages.

-

Pouch Seal Inspection — Airborne Ultrasound Technology For Better Process And Quality Control

A pouch seal is a structural element that joins flat film material and a component designed to close a pouch airtight. Traditional test methods (e.g. peel strength or burst), can measure the joint strength of the pouch seal using destructive methods that are often unreliable. Submitted by PTI Inspection Systems

-

Understanding Vacuum Decay Leak Testing

The ability to detect leaks is necessary to ensure consistency and integrity of packages. It is also important to detect leaks and defects that are not visibly detectable. VeriPac's non-destructive technology is capable of detecting package leaks and invisible defects using an absolute or differential pressure transducer leak test system. Submitted by PTI - Packaging Technologies & Inspection

-

Technology Overview: How To Leak Test Blister Packaging

Most current test methods for blister packages are destructive, time consuming, not sensitive, unreliable, and dependent on the properties of the package lidding material. Small semi-rigid, flexible, and multi-cavity blister packages do not have enough air inside the package to reliably detect defects by simple vacuum decay methods. Submitted by PTI - Packaging Technologies & Inspection

-

Understanding Pressure Decay Leak Testing For Bottles And Containers

Leak detection of empty containers — before the filling and sealing process — is an important step to insure container integrity. Applications in the plastic, blow molding, food, beverage and pharmaceutical industries all require some type of online container integrity system. Submitted by PTI - Packaging Technologies & Inspection

-

Blister Pack Leak Detection: Protecting Product Integrity

The blister packaging process for tablets and capsules is unique to the packaging industry in so many ways. Blister packaging will always exist due to its practicality; but, the things that make blister packaging difficult to work with also make it a desired product presentation. Submitted by PTI Inspection Systems

-

Container And Closure System Integrity Testing In Lieu Of Sterility Testing As A Component Of The Stability Protocol For Sterile Products

The purpose of stability testing is to provide evidence on how the quality of a substance or product varies with time under the influence of a variety of environmental factors such as temperature, humidity, and light, which enables you to establish or modify recommended storage conditions, retest periods, and shelf life or dating period, as the case may be.

NEWS AND ARTICLES

- Part II: Defining The Dye Ingress Operating Window

- Part I: Defining The Dye Ingress Operating Window

- Engineering Excellence In Container Closure Integrity Testing

- A Holistic Approach To CCI Is A Deterministic Approach

- Beyond Visual Inspection: Understanding Acoustical Transparency As A PAT

- Importance Of Implant Package Integrity

- Continuous Glucose Monitors

- Package Integrity Testing Of Sterile Instruments

- Best Practices For Safe And Accurate Tray Inspection

- Ensuring Integrity: Testing Viscous Biologics In Pre-Filled Syringes

- Determining The Limit Of Detection In CCIT