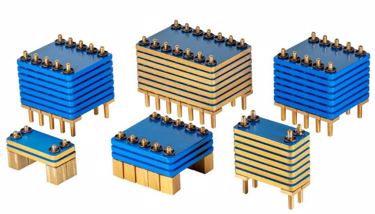

A Custom Approach To Large Capacitor Assembly

Achieving high capacitance means going big. But how do you do that while still maximizing board space? At Knowles Precision Devices, we’ve developed a new method for building customizable large capacitor assemblies that capitalize on the vertical space above the circuit board. While stacked capacitor assemblies have been around for many years, these parts do not have very good bump and vibration withstand due to the thin leads used in their construction. These new assemblies from Knowles Precision Devices offer a ruggedized construction capable of withstanding high levels of shock and vibration. This offers a unique combination of capability, durability, high capacitance, and very high voltage in a smaller area, making these capacitors ideal for automotive, military, and aerospace applications.

Our large capacitor assemblies are highly customizable both in height and shape and are built with reliability in mind. For these assemblies, we use large diameter pins that can handle high ripple currents and contact to the internal electrodes through a 360º connection, reducing resistive and inductive losses. The pins are mechanically decoupled from ceramic elements, allowing the assembly to withstand severe mechanical shock, vibration, and temperature variations. We also use a low-loss, ultra-stable C0G dielectric and have a high capacitance range of 10nF to 3.9µF and a voltage range from 500Vdc to 5000Vdc. These capacitor assemblies have also been through a variety of qualification tests as shown in Table 1 to demonstrate their capability.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.