Beyond The Quote: Choosing The Right Micro-Molding Partner For Long-Term Success

Brett Saddoris, Technical Marketing Manager, Accumold

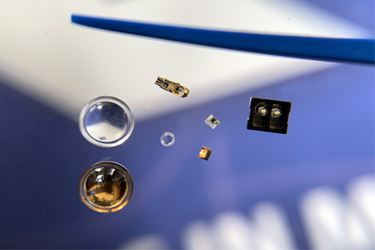

In high-precision manufacturing, particularly in sectors like medical technology, optics, telecom, and microelectronics, selecting the right micro molding supplier can determine whether a product succeeds or fails. Micro molding is no longer a niche process but a strategic necessity as devices become smaller, more complex, and multifunctional. However, not all suppliers are equal.

True micro molders have purpose-built infrastructure, micron-level tooling, and expertise in specialized materials such as PEEK, LCP, and biocompatible thermoplastics. Cleanroom environments, robust quality systems, and deep technical knowledge separate true specialists from companies that simply downscale injection molding equipment. OEMs should probe suppliers on their smallest produced parts, tolerances under 10 microns, and examples of challenging work.

Early collaboration is another hallmark of a reliable partner. The best micro molders engage during the design phase, offering guidance on material selection, gating, tolerancing, and manufacturability. Suppliers that only respond at the RFQ stage often lack the engineering foresight needed to solve problems during production.

Competency goes beyond certifications. Experience, case studies, vertical integration, and in-house metrology are critical indicators of capability. Accurate measurement of micron-scale features ensures quality and compliance, while process validation and statistical control reduce risk.

Long-term thinking also matters. Strategic partners support scaling from prototype to high-volume production, manage design refreshes, and maintain robust process documentation. Culture, transparency, and responsiveness often prove decisive.

With over 40 years of expertise, Accumold exemplifies these qualities—offering ISO-certified, vertically integrated micro molding with a culture of engineering collaboration. In micro molding, precision is measured not only in parts, but in partnerships.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.