Choosing A PCD Configuration For Your Cycle

By Crystal Hostler, Mesa Laboratories

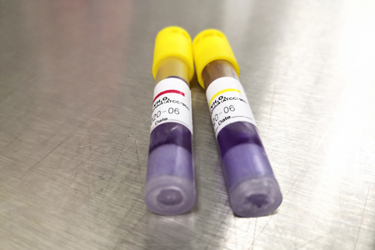

Ethylene Oxide (EO) has long been recognized as a highly effective sterilant, widely adopted for the large-scale industrial sterilization of medical devices and healthcare products. Its ability to penetrate complex device geometries and materials makes it indispensable in ensuring sterility assurance across a broad range of applications. A critical component in the development, validation, and routine monitoring of EO sterilization processes is the Process Challenge Device (PCD). These devices are specifically designed to simulate the most challenging areas within a sterilization load—those that are hardest to sterilize—by incorporating a microbiological challenge.

Mesa offers a comprehensive line of PCDs with nominal D-values ranging from 3 to 58 minutes. This extensive range provides users with the flexibility to select a PCD configuration that closely mirrors the resistance characteristics of their actual product bioburden. By aligning the PCD’s performance with the microbial challenge of the product, users can more accurately assess the efficacy and consistency of their sterilization process.

Whether you're validating a new EO cycle or ensuring ongoing compliance with regulatory standards, Mesa’s PCD solutions are engineered to support your quality assurance goals.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.