ABOUT US

Mesa Laboratories: Life Sciences and Critical Quality Control Solutions

Mesa Laboratories is a multinational leader in the design and manufacture of life sciences tools and critical quality control solutions for regulated applications in the pharmaceutical, healthcare, and medical device industries. Mesa offers products and services to help customers ensure product integrity, increase patient and worker safety, and improve the quality of life throughout the world. Mesa offers a breadth of products unified by a shared commitment to accelerate growth and innovation to care for communities worldwide. Whether it's environments, products, or people, Mesa is committed to protecting the vulnerable.

Mesa's comprehensive suite of life sciences tools enables manufacturers to validate sterilization processes, monitor environmental conditions, and ensure product quality from R&D through commercial manufacturing. Through precise measurement, monitoring, and validation, Mesa helps protect products, processes, and ultimately, patients across four integrated divisions.

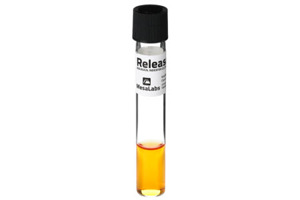

Sterilization and Disinfection Control

The Sterilization and Disinfection Control division manufactures and sells biological and chemical indicators that assess the effectiveness of sterilization and disinfection processes for pharmaceutical, healthcare, and dental industries. Mesa validates sterilization processes with a complete line of Biological and Chemical Indicators designed for steam, VH₂O₂, EO, and other modalities, ensuring product sterility and patient safety.

Clinical Genomics - Agena Bioscience®

Agena Bioscience® empowers research laboratories worldwide to deliver scalable targeted genomic data. The open, advanced MassARRAY® System provides researchers with insights through a highly multiplexed solution in the areas of mutation profiling, liquid biopsy, pharmacogenetics, and more. This platform provides affordable, accurate genomic analysis that supports precision medicine initiatives.

Biopharmaceutical Development - Gyros Protein Technologies

Gyros Protein Technologies provides automated systems for protein analysis and peptide synthesis solutions that accelerate the discovery, development, and manufacture of biotherapeutic drugs through two specialized businesses: Immunoassay and Peptide Syntehsis. Within our immunoassay business, the Gyrolab® platform uses groundbreaking microfluidic technology to automate immunoassays at nanoliter scale, helping laboratories reach their goals faster and deliver results that make a difference. Within our peptide synthesis business, scholars and scientists leverage our transformational peptide synthesis solutions that speed time to results.

Calibration Solutions

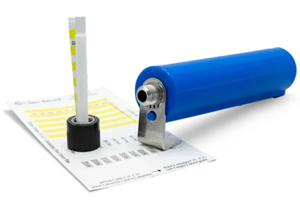

The Calibration Solutions portfolio uses the principles of advanced metrology to enable customers to measure and calibrate critical parameters in applications such as Environmental and Process Monitoring, Dialysis in Renal Care, Gas and Air Flow Measurement for Occupational Health, Ambient Air Ampling, and Cap Torque Testing. Mesa monitors critical environments with ViewPoint® Continuous Monitoring and DataTrace® data logging systems that provide real-time alerts and comprehensive data trails. Mesa ensures measurement accuracy with DryCal's flow technology and Torqo® cap torque testing systems for precise, reliable results.

Protecting What Matters Most

Mesa's products provide affordable, accurate genomic analysis, help monitor hazardous environments, ensure the sterility of medical instruments, and deliver proper functioning of lifesaving medical devices. Through continuous innovation and commitment to scientific excellence, Mesa Laboratories enables healthcare organizations, pharmaceutical companies, and medical device manufacturers worldwide to maintain the highest standards of quality and safety, ultimately improving the quality of life throughout the world.

CONTACT INFORMATION

Mesa Laboratories

12100 W. 6th Avenue

Lakewood, CO 80228

UNITED STATES

Phone: 303-987-8000

BROCHURES AND DATASHEETS

- Process Challenge Device (PCD®) Selection Guide

- An Introduction To Validation Of Aseptic Fill/Finish And Related Processes

- Biological Indicators To Fit Your Needs

- Spore Suspensions

- Biological Indicator Testing: Meeting Regulatory Demands With Confidence

- Vaporized Hydrogen Peroxide Biological Indicators

- Apex Spore Suspension

- Biological Indicator - Apex Ribbon

- Biological Indicator Designed For The Pharmaceutical Industry

- Biological Indicators - Apex Discs

FEATURED ARTICLES

-

Bowie-Dick test failures indicate serious sterilization issues. Learn the five most common causes and proven strategies to prevent downtime, compliance risks, and compromised product integrity.

-

Bowie-Dick testing is essential for compliance, but the choice between disposable and reusable systems impacts cost, waste, and efficiency. Learn how to balance sustainability with sterility assurance.

-

Bowie-Dick testing ensures steam sterilizers remove air and achieve full steam penetration. Discover why this simple check is vital for compliance, safety, and preventing costly sterilization failures.

-

Accurate PCD configuration ensures sterility assurance. Learn how to align validation strategies with ISO standards, optimize cycle efficiency, and select the right BI format for EO sterilization success.

-

Lowering EO levels is possible without sacrificing sterility. Learn how calibrated PCDs and precise cycle control can reduce risk and streamline validation for more sustainable sterilization.

-

Whether you're refining existing protocols or developing new ones, this guide serves as a valuable resource for ensuring safe, effective, and compliant sterilization outcomes.

-

Ethylene Oxide (EO) sterilization is essential for medical device safety. Explore how Process Challenge Devices help validate and monitor EO processes with precision across a wide range of applications.

-

PCDs are patented devices designed to meet the demands of EO sterilization. Gain insight into how they support process development, validation, and monitoring with reliable, reproducible performance.

-

Sterilization validation is vital in pharma and medical device manufacturing to ensure product safety and regulatory compliance. Explore essential principles, best practices, and frameworks for effective implementation.

-

Validating sterilization methods like steam, VH₂O₂, and EO is essential for safety and compliance. Learn best practices, avoid common pitfalls, and optimize your validation strategy effectively.

-

Effective sterilization is vital in manufacturing. Discover how the Bowie-Dick test ensures vacuum sterilizer performance, safeguards patient safety, and strengthens your sterility assurance program.

-

D-values are essential for ensuring sterility in pharma and medical device manufacturing. Explore a simplified concept that helps professionals optimize sterilization processes and ensure product safety.

-

Discover why biological indicators are the gold standard for sterilization validation in pharmaceutical and medical device manufacturing, as well as how choosing the right one ensures safety, compliance, and product integrity.

-

Sterility is non-negotiable in pharmaceutical and medical device manufacturing. Discover the top five sterilization challenges facing manufacturers today and the proven strategies to overcome them while ensuring compliance and safety.

-

Understanding how a product influences microorganisms' resistance is crucial. Read about relevant standards and references as well as recommendations for performing product D-value studies.

-

Utilizing tape for positioning during Sterilize in Place (SIP) validation can introduce numerous issues. Explore the top eight reasons why tape should be avoided during SIP validation cycles.

-

Explore the Biological Indicator/Bioburden (BI/BB) method for achieving sterilization of products along with the prerequisite studies needed to develop the sterilization process.

-

Understand the importance of biological indicators, and learn why they should be integral to any comprehensive sterilization program.

-

Gain a deeper understanding of the requirements, guidelines, and best practices for Annex 1 compliance whether you're in pharmaceuticals, healthcare, or any field utilizing biological indicators.

-

Learn about liquid submersible biological indicators (LSBI), including the three basic LSBI formats, and how caramelization due to long sterilization cycles affects the media's ability to promote spore growth.

-

How can your organization use this critical tool when developing your sterilization process for heat-sensitive products and low F0 cycles?

-

Follow a discussion on non-heat sensitive aqueous liquid product sterilization and the use of the Overkill method and Bioburden/BI method.

-

Learn about what questions to ask when developing a sterilization method and a critical tool that can help guide your decisions.

-

Here, we review the information concerning biological indicators in European Pharmacopoeia General Chapter 5.1.2, which is more detailed and covers a wider scope than the previous version.

-

We review what to do should you ever find yourself in the situation where the probes indicate conditions that would render killed BIs, yet the units are testing positive.

-

We highlight vapor hydrogen peroxide (VH2O2) biological indicators (BIs) including necessary physical characteristics of the BI unit, BI types, proper BI placement, and challenges encountered.

-

This field guide uses current published resources to provide clarity and direction regarding best practices for validating decontamination processes using VH2O2.

-

We discuss the three general BI types used for monitoring the VH2O2 cycles and directions on their proper placement in the isolator.

-

We discuss the concept of using triplicate biological indicators (BIs), not as a reaction to having obtained an unexpected growth-positive BI in your vaopr hydrogen peroxide cycle, but as a proactive measure.

-

We review the potential benefits and difficulties of using Vapor Hydrogen Peroxide (VHP) in decontamination and sterilization.