3D Printed Implant Promotes Meniscus Regeneration

By Chuck Seegert, Ph.D.

Replacing the knee’s meniscus, the protective layer that the joint slides on, has been approached in a novel way by Columbia University researchers. The team printed a personalized 3D scaffold, and loaded it with growth factors that helped turn it into a collagen-like tissue when implanted. Tested successfully in sheep, it could provide a long-lasting repair option to millions of patients.

The meniscus is a connective tissue shock absorber that separates the bones in the knee joint. It can be damaged in any number of ways, but methods for repairing this vital structure are currently very limited. Occasionally, a tear can be sewn back together, or small defects can be trimmed using minimally invasive methods. For larger defects, the meniscus can be removed, which may help with pain in the short-term. Unfortunately, removing the meniscus generally leads to joint degeneration and arthritis over time.

Research from Columbia University may now allow a full replacement of the meniscus, according to a recent press release. The meniscal replacement procedure is based on a 3D printed replicate of the tissue that is generated using CT data and is accurate to within about 10 microns. The scaffold is made from polycaprolactone, a resorbable polymer, and is loaded with growth factors. These growth factors induce stem cells to infiltrate the scaffold and to begin creating collagen-like connective tissue.

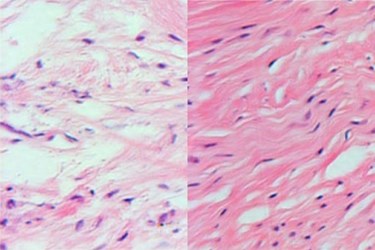

Historically, attempts at similar replacement strategies have been unsuccessful because they have tried to load cells onto the implant ex-vivo, according to a study published by the team in Science Translational Medicine. The Columbia team, however, used a different strategy and loaded only growth factors, which induce endogenous cells to fill the matrix. While the physiologic environment uses a cascade of growth factors, the team was able to narrow their cocktail down to only two: connective tissue growth factor (CTGF), and transforming growth factor–β3 (TGFβ3).

“This is a departure from classic tissue engineering, in which stems cells are harvested from the body, manipulated in the laboratory, and then returned to the patient—an approach that has met with limited success,” said Dr. Jeremy Mao, Ph.D., the Edwin S. Robinson Professor of Dentistry in Orthopedic Surgery at the Columbia University Medical Center, in the press release. “In contrast, we’re jumpstarting the process within the body, using factors that promote endogenous stem cells for tissue regeneration.”

Though using only two growth factors, the design used them in a sequential fashion, one after the other, according to the press release. This more closely approximated the growth factor cascade that occurs in normal tissue healing and was accomplished by using slowly dissolving microspheres. After about six weeks, the meniscus was regenerated and the scaffold had begun to dissolve. The procedure was tested on 11 sheep for three months, by which time the sheep were walking normally.

Studies are now underway to determine if the tissue replicate is as long-lasting as it would need to be for true meniscal repair, according to the press release. The team is hopeful that clinical studies are in the near future, and they are in the process of obtaining funding.

Manufacturing implants using 3D printing has also been performed in other orthopedic settings where a significant level of customization is required. For example, the FDA recently approved a 3D printed system for custom craniofacial implants.

Image Credit: Lab of Dr. Jeremy Mao