Designing Extrusions With Additional Processing

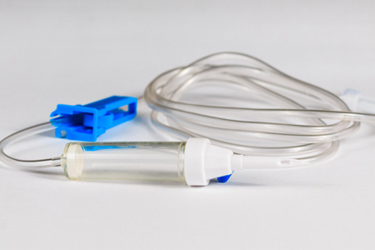

A leading medical device company recently teamed up with Nordson MEDICAL to redesign a crucial component for a specialized medical device. Initially, Nordson MEDICAL was tasked only with manufacturing tubing as per the customer’s requirements. However, their ability to incorporate device-specific features impressed the client, leading to an expanded role that included both extruded tube production and secondary operations.

To ensure successful collaboration, Nordson MEDICAL developed a detailed project plan in close partnership with the customer. In just 15 days, they produced prototypes for evaluation, demonstrating their efficiency and expertise. Furthermore, they implemented automation techniques to reduce costs and streamline the supply chain, enhancing their overall value proposition. The entire project was completed within six months.

Thanks to Nordson MEDICAL’s dedication and proficiency, the customer successfully launched the redesigned component to the market. The company now continues to depend on Nordson MEDICAL for efficient tubing production, consistently meeting price and cost objectives. This partnership underscores the importance of choosing the right collaborator for critical component redesigns. Nordson MEDICAL's expertise in extrusion and ability to integrate specific features were key to the project’s success, highlighting their commitment to addressing customer needs effectively and efficiently.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.