Increasing Print Quality In Industrial Inkjet Systems

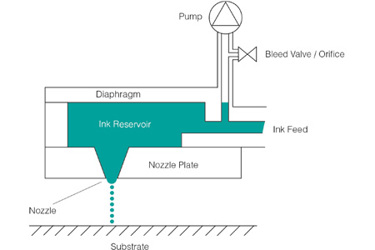

In industrial inkjet printing, maintaining precise meniscus pressure at the printhead is critical for achieving high-quality, accurate droplet formation and placement. Poor meniscus control can cause air ingestion, nozzle flooding, or pressure pulsations—each leading to irregular jetting, landing errors, and compromised print quality.

Traditional systems often use motor-driven diaphragm pumps to provide meniscus bias pressure. While functional, these pumps produce pulsations and have limited controllability, requiring additional components such as pulsation dampers and proportional valves. This increases system size, complexity, and cost, while limiting design flexibility—particularly in modular printer configurations or when tailoring bias pressure for multiple printheads.

The Lee Company’s disc pump technology provides a more efficient, compact, and precise alternative. Disc pumps produce a smooth, pulsation-free output with exceptional controllability, eliminating the need for additional pneumatic components. Their small footprint enables direct integration with printheads, supporting a fully modular approach where vacuum levels can be customized for each head or group of heads.

By simplifying the ink delivery system, disc pumps reduce overall footprint, enhance design freedom, and support faster servicing or customization. The result is stable, precise meniscus pressure control, ensuring consistent droplet shape, placement, and print quality at high speeds.

This combination of precision, reliability, and compact integration makes The Lee Company’s disc pumps ideally suited for next-generation industrial inkjet systems, where print quality, efficiency, and modularity are paramount.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.