Injection Molding Of Thin Wall Cannulas — A Lesson In Expertise & Persistence

By Paul Runyan, VP of Sales, Accumold

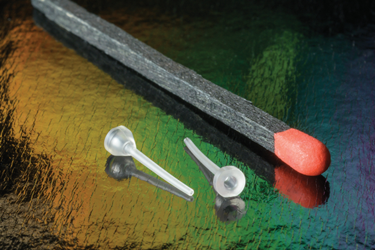

After 5 years of painstaking work, leading micro molding innovator Accumold has developed a way to micro injection mold thin wall cannulas in very high volumes. Previous to this innovative approach to production, cannulas were typically produced via an extrusion process, which is at the same time expensive, prone to high fall out rates, and which does not lend itself to the high volumes required by medical device OEMs for some applications.

It took Accumold 5 years to perfect the micro injection molding of thin wall cannulas at volume, and this article describes how it was done, the issues at play when micro injection molding such intricate devices, the advantages of the micro injection molding process, and what this means for medical device applications moving forward.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.