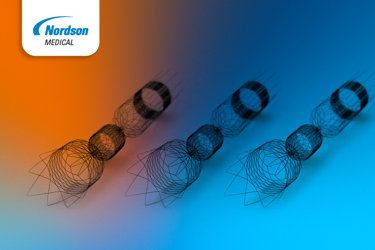

Nitinol Wire Forming and Manipulation for Custom Components: Meeting Customer Requirements

With its shape memory properties, nitinol wire is a highly suitable material for a range of medical applications. Given its exceptional mechanical and thermal properties, the demand for nitinol products is on the rise.

This paper delves into the process of forming and manipulating nitinol wire to create customized components.

What Is Nitinol?

Nitinol wire is a shape memory alloy made from a combination of nickel and titanium. Nitinol wire has two distinctive properties, namely superelasticity and shape memory. Superelasticity refers to the ability of nitinol wire to recover its original shape after being deformed, while shape memory refers to its ability to “remember” its original shape and recover it upon heating. These properties, along with biocompatibility, make nitinol particularly useful in medical applications, where precise and consistent shape recovery is essential and designs must be flexible.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.