Optimizing Outcomes Through Micro Molding

By Craig Tappe, Sales Engineer at Accumold

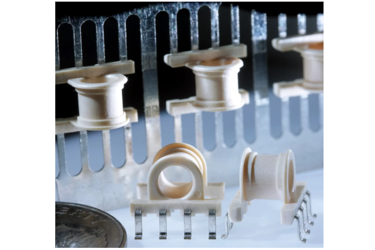

For companies that are exploring the possibilities that exist for miniaturization of plastic parts and components, there are some seemingly daunting obstacles that exist, not least the vagaries of the micro molding process itself. Molding at the micro scale renders redundant many of the “rules” associated with macro molding, and the process requires a completely new perspective in terms of such considerations as rheology, tooling, gating, and handling and assembly to name but a few.

Because of this, most OEMs that embark on a micro molding product development process engage with specialist micro molding experts that can navigate inherent issues, and through experience have honed the art of micro molding to optimise manufacturing outcomes. However, not all micro molding companies are the same, and in this Q&A interview, Craig Tappe, Sales Engineer at Accumold discusses various aspects of the micro molding process, and discusses why it is important to ensure that when short-listing your preferred suppliers, the correct questions are asked.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.