Soft Or Semi-Hard Tooling For Micro Molding?

By Craig Tappe

Soft or semi-hard tooling and CNC machined cavities are a great solution for non-critical larger parts, but are not ideal for micro molding projects where small tolerances, sharp corners, and micro part features must be achieved. This has always been the struggle with micro-sized parts and larger parts with small critical features.

Many R&D engineers and design engineers have heard the same responses from molding suppliers who utilize soft tooling and machine cavity/core details with CNC milling machines. They often are forced to request adjustments to the part design. There’s a major tradeoff when adjusting part designs to accommodate soft machined prototypes or semi-hard production tooling.

What Happens When Mold Suppliers Request Adjustments To Part Design?

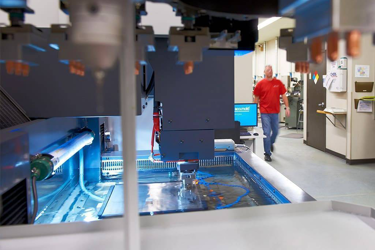

Adjusting your part design often results in a functional sacrifice and may increase risk of finished product performance issues caused by the adjusted features. In many cases, OEMs have to adjust their designs to such a degree that the components lose critical features. As companies push more functions into smaller forms, in a growing number of cases these forced design changes have a major effect on final product function. Thin ribs, small hole diameters, and sharp corners on parts are the usual suspects that give molding suppliers a hard time with soft machined tooling. These are often impossible to achieve without hard tool steel mold components and utilizing traditional EDM machining, wire EDM, or Sarix EDM machining processes.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.