The Importance Of Material Selection In Micro Molding Applications

By Paul Runyan, VP Sales & Marketing, Accumold

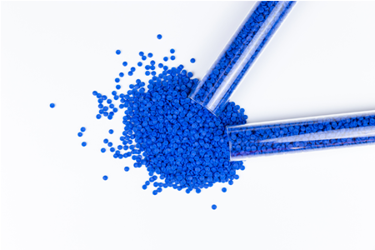

Precision is key in the world of micro molding, where the selection of materials plays a critical role in defining product performance and reliability. This article delves into the relationship between material properties and micro molded components, highlighting crucial attributes such as strength, flexibility, and thermal resistance that impact functionality. Micro molded components, used in various applications ranging from medical devices to portable electronics, face relentless stress. The materials used to create these tiny components must possess strength, resilience to fatigue, and the ability to withstand thermal extremes.

Flexibility is another crucial factor to consider, as it ensures that components can bend without breaking while maintaining their structural integrity over numerous cycles. The process of molding is not only about identifying off-the-shelf materials but also customizing formulations to exact specifications. Manufacturers like Accumold are leading the way in precision engineering by leveraging their deep knowledge of material science and their unwavering commitment to quality, as demonstrated through rigorous testing protocols that ensure only materials meeting the highest standards are produced.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.