The Ultimate Guide To Biological Indicators: What They Are, Why They're Crucial, And How To Choose The Right Ones

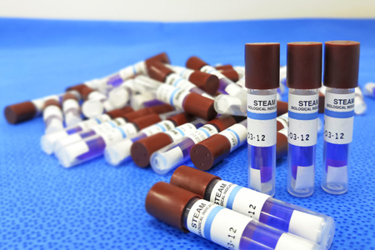

Sterility in pharmaceutical manufacturing and medical device production isn’t just a regulatory requirement—it’s a cornerstone of patient safety and product integrity. To ensure that sterilization processes are truly effective, manufacturers rely on a critical tool: biological indicators (BIs). These indicators are widely regarded as the gold standard for validating sterilization methods, providing concrete evidence that harmful microorganisms have been effectively eliminated. But what exactly are biological indicators? Why are they so vital in high-stakes environments like cleanrooms and sterile processing facilities? And with various types available, how do you determine which BI is best suited for your specific sterilization method—whether it’s steam, ethylene oxide, hydrogen peroxide, or radiation?

This article will walk you through the fundamentals of biological indicators, explain their role in compliance and quality assurance, and help you make informed decisions when selecting the right BI for your application.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Med Device Online? Subscribe today.