BYU Researchers Develop Flexible Glass For Microfluidic Nanodevices

By Jof Enriquez,

Follow me on Twitter @jofenriq

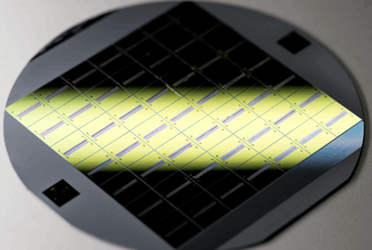

Researchers at Brigham Young University (BYU) have developed a new method to fabricate flexible nano-scale membranes using surface micromachining and silica thin films. These devices are an improvement over existing lab-on-a-chip and microfluidic devices that operate on the microscale, and therefore can be used to test smaller quantities of a substance.

Microfluidics and lab-on-chip designs are one of the most active focus areas for research globally. Different groups have demonstrated applications in cancer diagnostics, blood storage, drug testing, and drug delivery, to name a few. While most of these devices can function on the microscale, developing them to operate at the nanoscale can open up even more possibilities for diagnostics and therapeutics.

To that end, BYU researchers, led by electrical engineering professor Aaron R. Hawkins, developed a new fabrication technique to make tiny yet flexible glass membranes to perform nanoscale laboratory work.

Hawkins and fellow researchers John M. Stout and Taylor M. Welker explained in the paper Electrostatically actuated membranes made from silica thin films, published in Applied Physics Letters: "Standard microfabrication techniques are used, and the membrane can be moved using electrostatic forces. The degree of deflection is set by an applied voltage, and the devices can be fully collapsed (100 nm movement) by applying approximately 150 V. Deflection tests were performed using an optical profilometer when the area under the membrane was filled with air and water."

These flexible, nano-scale membranes allow chemists and biologists to move, trap, and analyze very small biological particles like proteins, viruses, and DNA, which will not react with the glass material. Glass also is non-toxic, easy to clean, and made more flexible with BYU's research.

"If you keep the movements to the nanoscale, glass can still snap back into shape," Hawkins said in a news release. "We’ve created glass membranes that can move up and down and bend. They are the first building blocks of a whole new plumbing system that could move very small volumes of liquid around."

BYU's nanodevices also require smaller amounts — just a drop or two of blood, for instance — to process and analyze at the point of care.

"Instead of shipping a vial of blood to a lab and have it run through all those machines and steps, we are creating devices that can give you an answer on the spot," said Hawkins. "This has the promise of being a rapid delivery of disease diagnosis, cholesterol level testing and virus testing. In addition, it would help in the process of healthcare knowing the correct treatment method for the patient."

Point-of-care diagnostics is expected to be the biggest opportunity for microfluidic technologies, whose worldwide market is forecast to reach nearly $4B in 2020, according to Lux Research.